How to do a good anti-oxidation treatment of metal mesh curtain oxidation is not a good thing. The oxidized aluminum plate will become unsightly, which is also a loss for users. Alumina plates are almost useless.

In terms of packaging, the control of temperature and humidity is very important for metal mesh curtains. Therefore, the humidity of the wooden shaft and the box board should not exceed 18%, and the temperature of the aluminum roller should not exceed 45°C.

If the metal mesh curtain is transported from a low temperature area to a high temperature and high humidity area, do not open the sealed package immediately. In order to allow Wuxi aluminum plates to have time to adapt to these environments, aluminum rollers should not be placed on the roofs of workshops and warehouses where rain and snow leak. Air drying management should be strengthened to ensure that there is no water in the compressed air. In addition, strengthen the management of rolling oil and control its water content below 0.04%. The packaging of aluminum foil should be sealed, and the quantity of desiccant should be placed in each roll. Reduce the contact between the surface of the aluminum plate and air and water, and take these measures to prevent the oxidation of the aluminum plate, which plays an important role in protecting the aluminum plate.

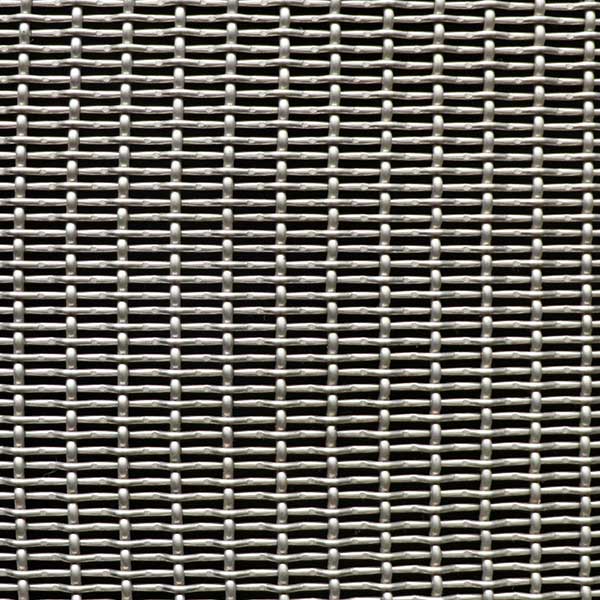

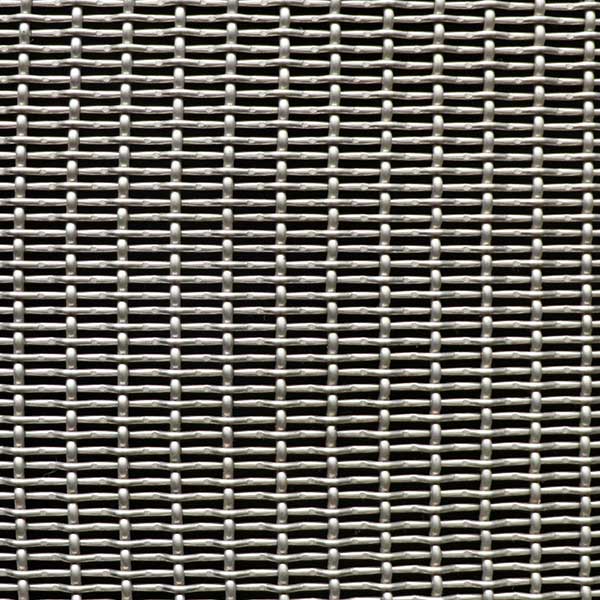

One of the key points of the metal mesh curtain is that the aluminum punching plate is made of CNC punching aluminum. Due to the special material of the aluminum plate, scratches sometimes appear during the stamping process, which affects the appearance and use. To avoid this, a thin plastic film can be coated on the aluminum plate. Lamination is a physical process. The aluminum film layer is formed by high temperature and high pressure. The coating process has many advantages, will not be oxidized by air and moisture, and reduce the damage of the aluminum plate during the production process.

.jpg)

.png)