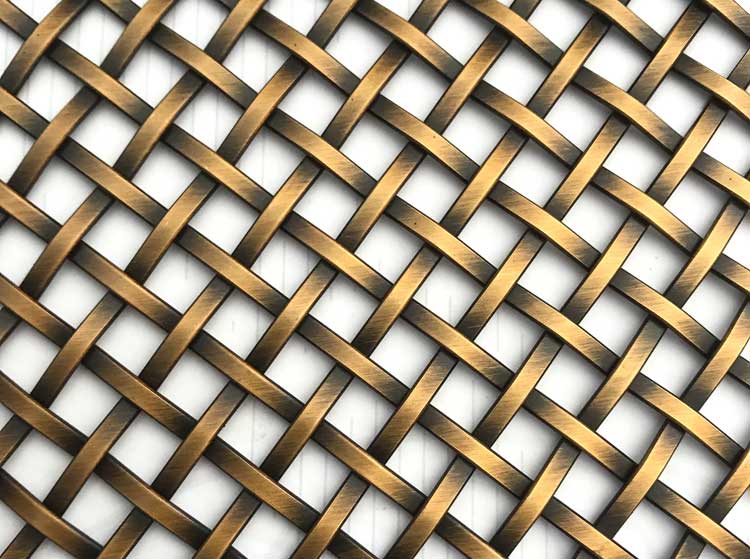

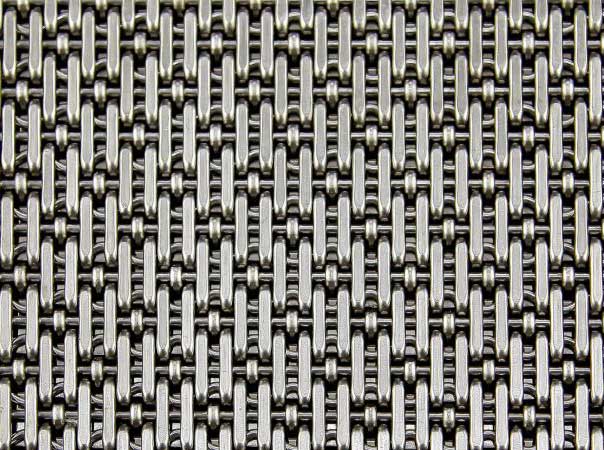

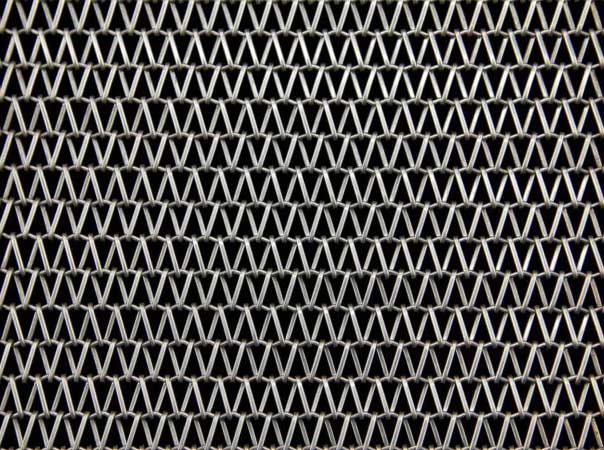

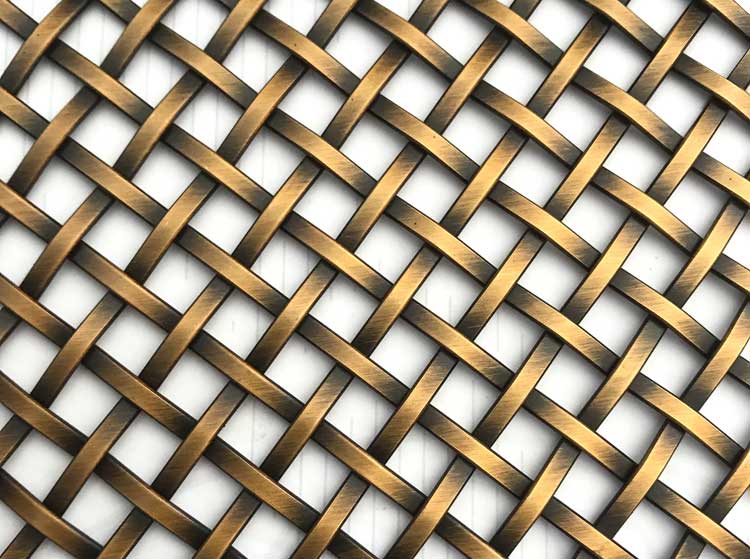

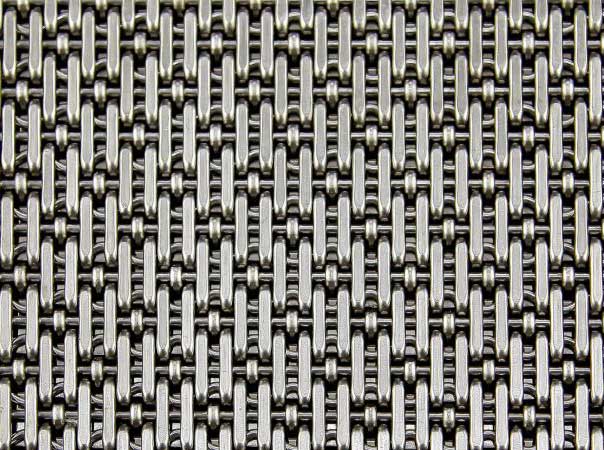

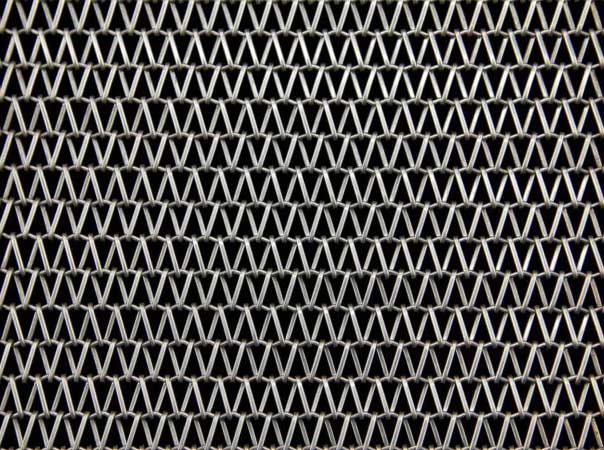

The metal mesh is formed by stretching and expanding a metal sheet through equipment to form a metal mesh with a uniform aperture. It is collectively called a metal stretched mesh. Due to the different hole shapes, it is also called: diamond stretched mesh, hexagonal stretched mesh, Also known as: stainless steel stretched mesh, metal expanded mesh, metal plate mesh wall, etc.

The most common materials of metal stretched decorative mesh are aluminum plate mesh, aluminum foil mesh, brass plate mesh, copper plate mesh, stainless steel plate mesh, nickel plate mesh, etc.

Metal stretched decorative mesh products have the following characteristics: flat mesh surface, flexible aperture, high tensile strength, aging resistance, non-deformation, easy welding, surface wear resistance, light weight, and low price.

Manufacturing process of metal stretched decorative net:

Stamped; pided into small expanded metal mesh, expanded metal mesh and stainless steel mesh.

Stretched: beautiful, sturdy and durable.

Surface treatment of metal stretched decorative mesh:

PVC dipping (plastic spraying, plastic coating), hot-dip galvanizing, electro-galvanizing, anodizing, spraying anti-rust paint, etc.

use:

Widely used in: building facades, indoor partitions, metal decorative mesh screens, metal decorative mesh ceilings, metal decorative mesh walls, metal decorative mesh curtains, balconies and corridors, etc. It is now used in high-end interior and exterior decorations such as airports, hotels, exhibition halls, opera houses, office buildings, shopping malls, bars, and private residences.

.jpg)

.png)