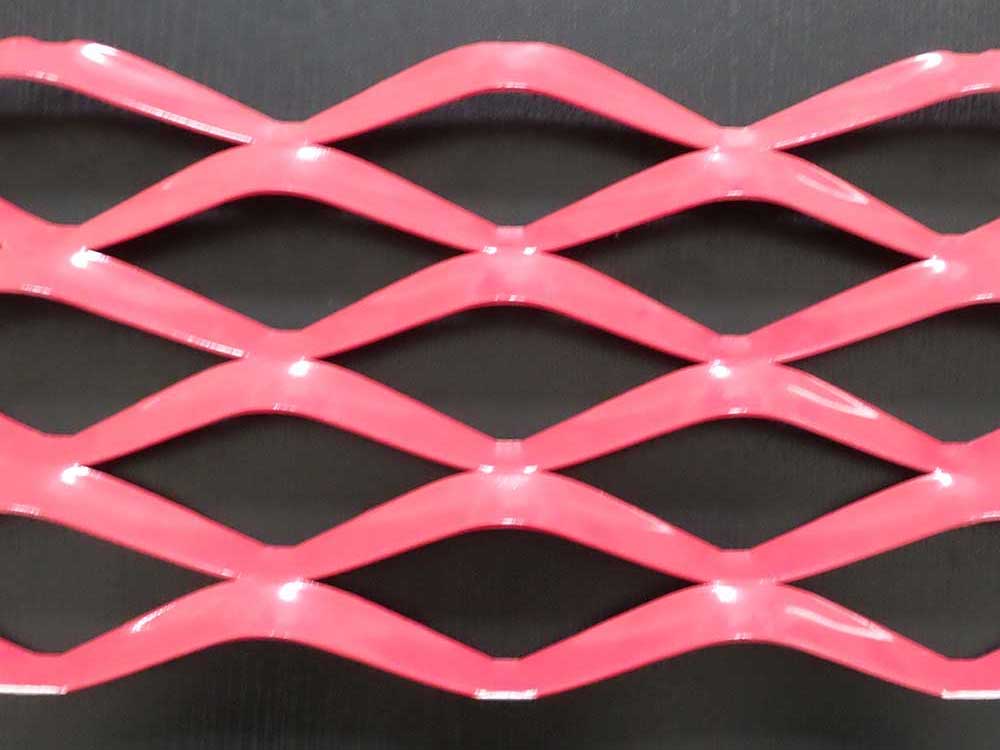

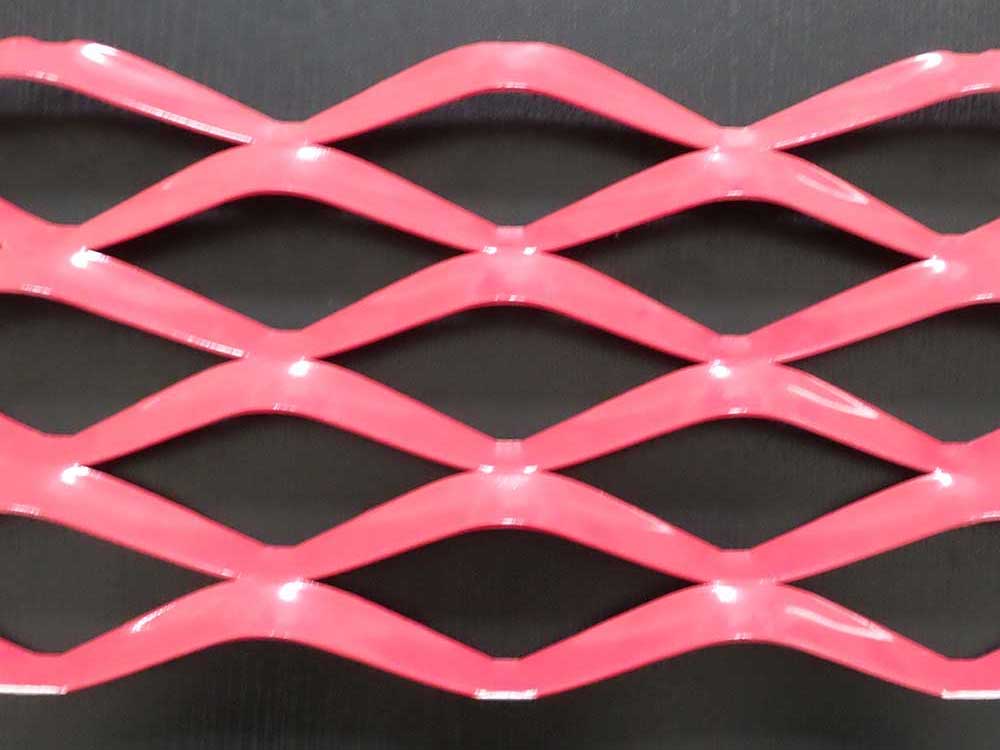

In fact, the stainless steel expanded metal mesh is easy to understand. It is a net-like product made of stainless steel, which can be formed after the material is stretched. Don't think that stamping and drawing is very simple, but in fact it is not. In our actual operation, everyone will find that it is not so easy, so we should pay attention to it when making stainless steel expanded metal mesh.

Since the strength of the stainless steel expanded metal mesh and its tensile strength are very high, and the processing hardness of stainless steel is also relatively large, so its rebound and cross tools may be damaged. In order to avoid similar problems, it is right Stainless steel expanded metal also has higher requirements for processing equipment.

As the processing equipment of stainless steel expanded metal mesh, it has certain humidity and rigidity, and wear resistance is also indispensable; also, its heat transfer is relatively small, but the thermal expansion will be relatively large, so just choose the water-soluble cooling performance Lube is just fine.

In the process of using stainless steel expanded metal mesh, it is necessary to ensure that its surface will not be damaged, so as not to affect its service life. But it is still difficult to really achieve this. When we press the surface of the stainless steel expanded metal mesh, it may also be damaged.

In this case, the steel plate should be treated with lubrication on the surface coating of the stainless steel expanded metal to prevent this problem from occurring, make the product more effective, and prolong the service life of the stainless steel expanded metal.

.jpg)

.png)