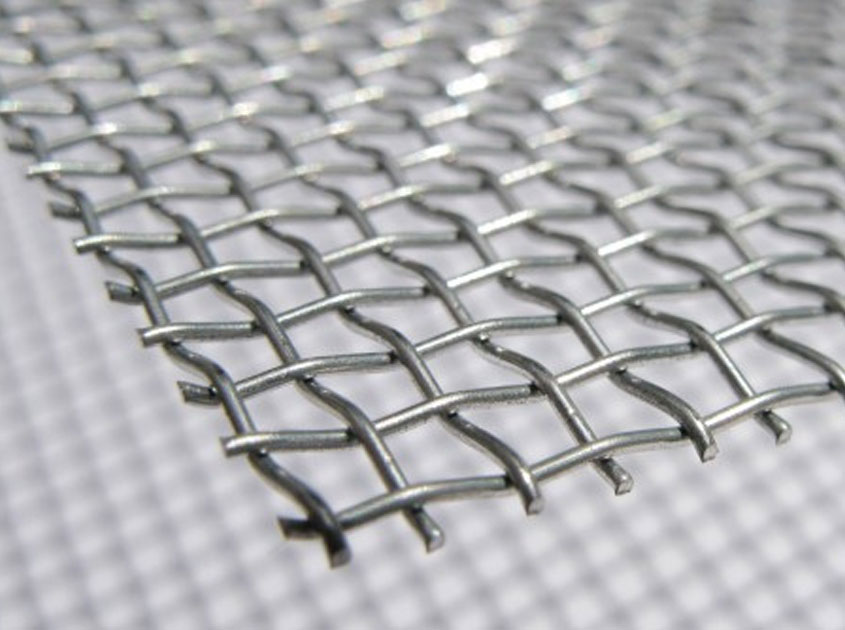

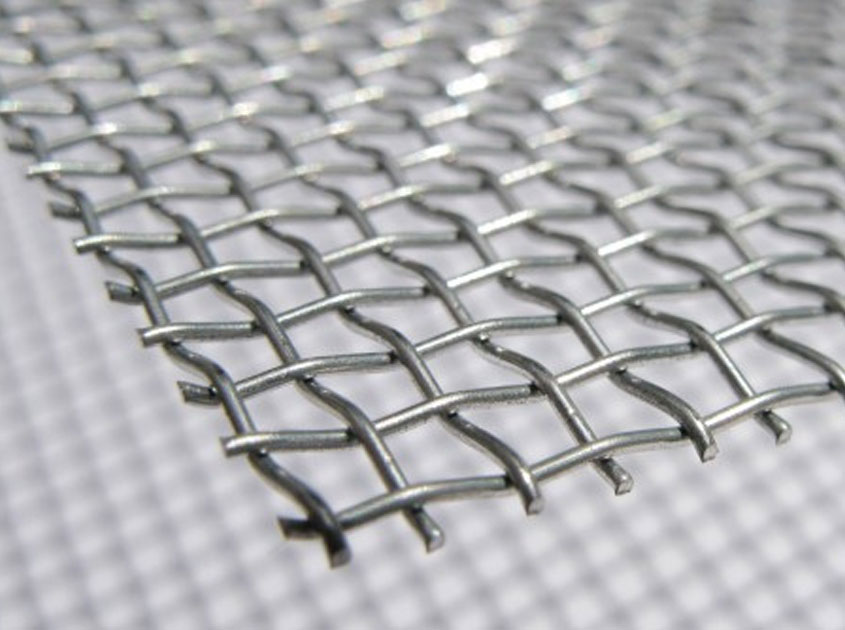

In the production of stainless steel mesh, welding occupies a more important link. If welding is not a good process, there is no way to make the product have good quality. It is precisely because of this that when users use this product, they will first have requirements for the welding process. Of course, as a manufacturer, I also hope that its products can improve the welding process, but if you want to improve the welding process, you also need to let the manufacturer have many conditions. If a manufacturer does not have the production conditions With the corresponding improvement, it is difficult to make it have a good craft.

First of all, it is necessary for the manufacturer to use advanced equipment in the production of stainless steel mesh. Because the current production of products is no longer pure manual welding, they are all integrated welding equipment. Some manufacturers are relatively behind in equipment. Although they can also produce products, they will have many shortcomings, or There is not enough uniformity in welding, or there is no good surface treatment in welding, which will not only affect the appearance of the product, but also have a great impact on the firmness of the product. Therefore, the user chooses this product At the time, we must first look at the equipment and strength of the manufacturer.

In addition to the equipment strength, the manufacturer also needs to have a good technical strength. If there is no strong technology in the welding process of stainless steel mesh, although it can be produced, the process will not be greatly improved. Although many equipments are now automated, the operation is determined by people. In addition, in production, it is also necessary to have good management strength, because when there is no improvement in management, the requirements for the production process will decrease.

.jpg)

.png)