You can contact your supplier to provide you with a

filter disc that meets your specifications. The filter disc must be adjusted to suit your different projects.

Long service life The materials used by the manufacturer are strong enough to extend the service life. Most of them are stainless steel that is not easily damaged. The equipment can also perform well under high pressure, thereby improving durability. Explains the working principle of the filter disc. It explains the process of fluid passing through to eliminate impurities in the fluid.

The working principle of disc filter In this section, you will learn the process of filtering fluid using filter disc. The most important filter element in the filter pan is the filter section with a fabric coating. Please note that water will flow through the internal space of the filter segment, and the fabric will trap impurities in the water. The filter disc may have one or more layers of rings or filter discs, each disc has 12 segments, and the number may vary according to the filter disc The type varies. Here, the number of filter discs will determine the capacity of the filter disc; the more the number of filter discs, the greater the capacity of the filter disc; the number of layers will also determine the capacity of the filter disc. Filter quality.

The more layers, the higher the filtering quality. The water will flow through all the layers of the filter pan and then flow out of the outlet of the filter tank. Different types of filter discs can perform different functions.

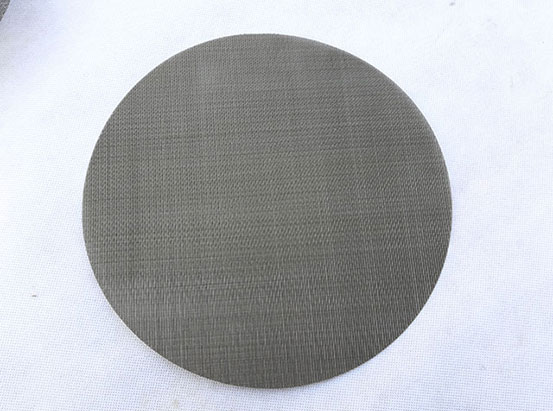

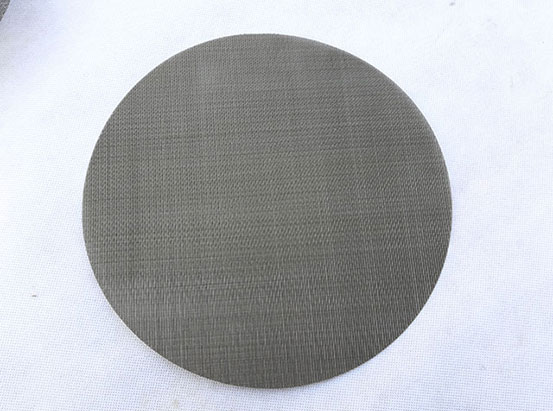

Manufacturers have different designs for different types of filter discs, which will affect the performance level. Types of filter discs In this section, you will learn about different types of filter discs, for example: ·Filter This type of filter disc has two types: flat filter tip and flat filter tip. Pleated version. You can decide whether to use the pleated version or the flat version according to the application requirements. Mesh filter discs are the best choice for cleaning and protecting gas or liquid flow systems. They are cost-effective and can be widely used in filter-like installation areas. ·

Fiber

filter disc You can use different types of fiber disc filters in gas and liquid applications. You can also find fiber disc filters in two forms, pleated or flat, that suit your requirements. In order to save space and money, you decide to buy a cheap flat plate. It may not be as effective, so it can only be used in liquids with few contaminants. c has a larger filtration area, a very low pressure drop and a smaller footprint. The design can provide different filtration rates and micron grades. ·Powder filter discs The types and sizes of metal powder filter discs are different. The range of diameter and thickness varies. Manufacturers use powder metallurgy technology to manufacture powder filter discs with different porosities.

.jpg)

.png)