Applications of Metal Mesh in Different Industries

Metal mesh has a wide range of applications in different industries. In the construction industry, metal mesh is often used for protection and decoration. For example, stainless steel mesh can be used to prevent small animals from entering balconies and windows, and aluminum mesh can be used to cover ventilation openings of buildings. In the automotive industry, metal mesh can be used to manufacture car seats and air conditioning filters. In the electronics industry, metal mesh can be used for PCB board printing, EMI shielding, and cell phone antennas. In the medical industry, metal mesh can be used to manufacture surgical instruments and artificial organs.

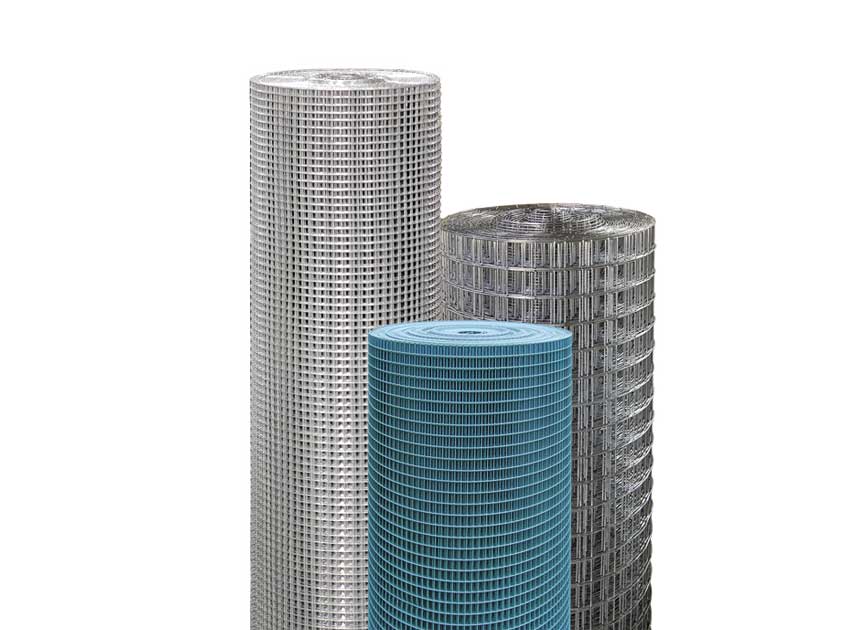

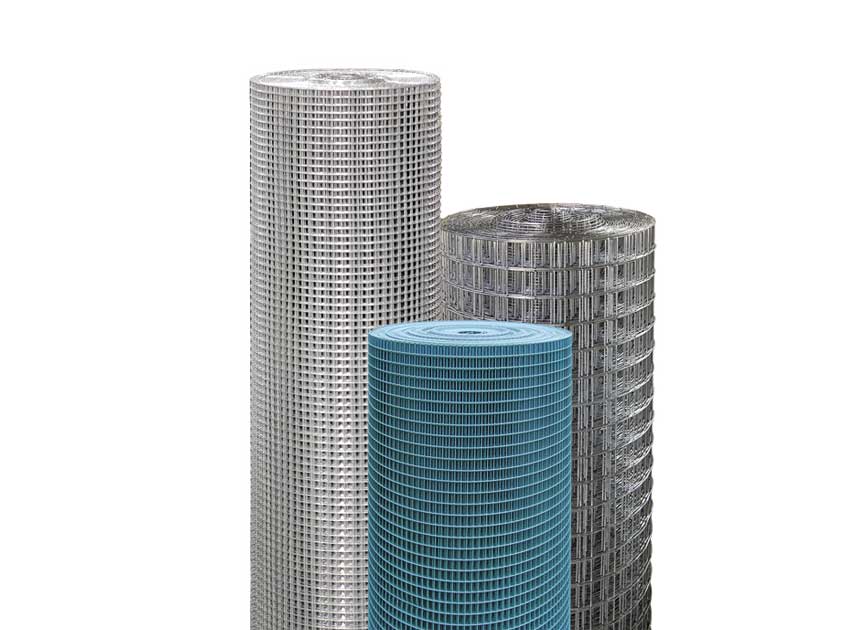

Different Types of Metal Mesh

There are several types of metal mesh, including stainless steel mesh, copper mesh, galvanized mesh, and aluminum mesh. Stainless steel mesh is the most commonly used type because it has excellent corrosion resistance, strength, and high-temperature resistance. Copper mesh is suitable for EMI shielding and circuit board printing applications. Galvanized mesh has corrosion resistance and durability, and is commonly used for decoration and building materials. Aluminum mesh is lightweight, high-strength, and suitable for the automotive industry, air purification, and aerospace fields.

Manufacturing Process of Metal Mesh

The manufacture of metal mesh requires selecting suitable materials, designing mesh openings, and conducting production processes. Firstly, it is necessary to select suitable materials, usually stainless steel, copper, aluminum, and galvanized steel wire. Secondly, the mesh openings need to be designed, usually using CAD software. Then, the steel wire needs to be stretched, cut, welded, and adjusted, followed by surface treatment and packaging.

Quality Control of Metal Mesh

Controlling the quality of metal mesh is crucial. Firstly, the materials need to be tested, including tensile testing, chemical composition analysis, and microscopy observation. Secondly, the mesh openings' size and shape need to be controlled, including the mesh diameter, wire diameter, and mesh spacing. Finally, a visual inspection is necessary to check for surface cracks, oxidation, or deformation.

Future Development of Metal Mesh

Metal mesh will continue to develop and innovate in the future. The application of metal mesh will continue to expand, especially in the fields of energy, environment, and biomedicine. New materials and manufacturing technologies will be developed to improve the performance and quality of metal mesh. The trend of intelligent manufacturing and automation will also bring new changes to the production of metal mesh.

.jpg)

.png)