Part 1: Corrosion resistance of razor wire

Razor wire is usually manufactured from high-quality materials such as stainless steel or galvanized steel wire. These materials have excellent corrosion resistance and are resistant to attack by moisture, chemicals and other corrosive elements. Whether in indoor or outdoor environments, razor wire maintains the integrity and performance of its surface, extending its lifespan and ensuring its long-lasting resistance to corrosion.

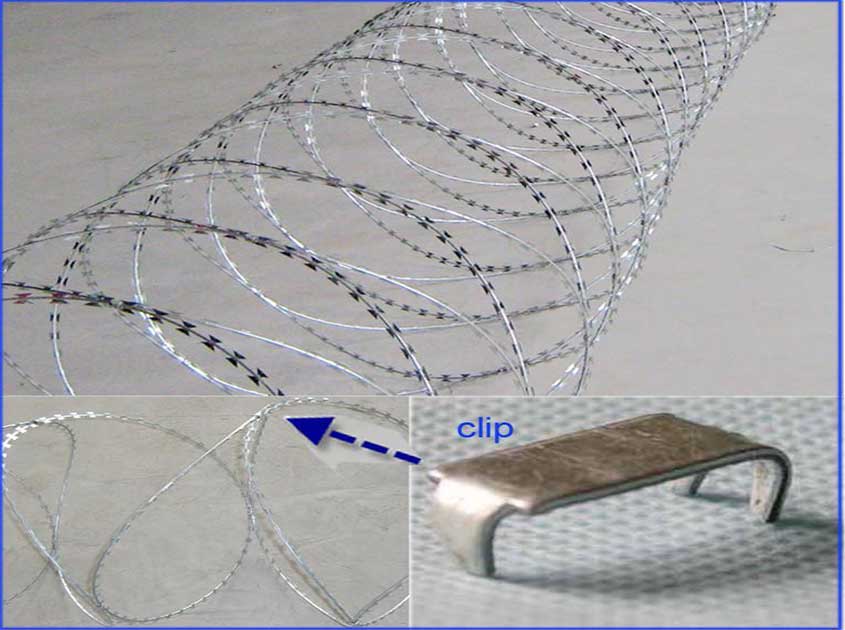

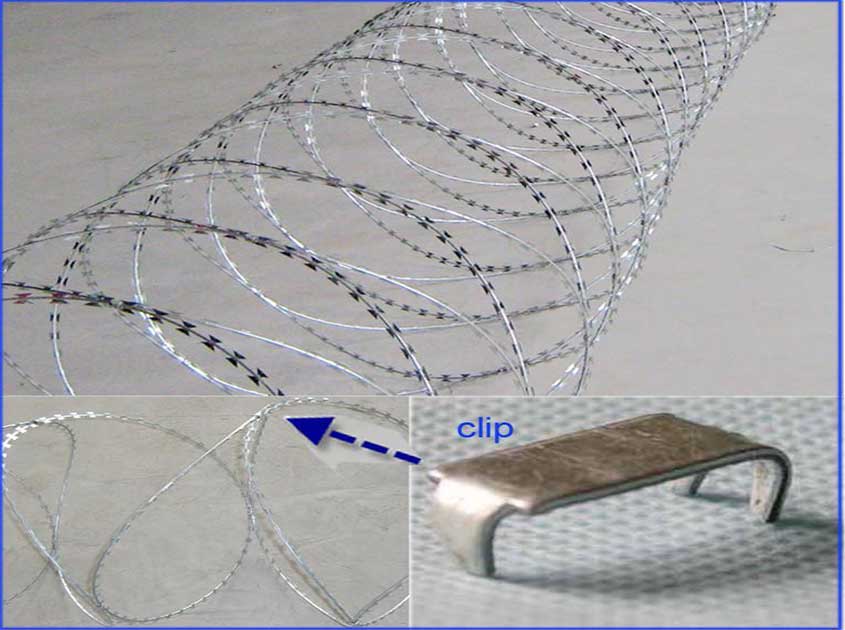

Part II: Durability of Razor Wire

Razor wire is known for its sturdy construction and high-quality materials. Blades are often specially treated to increase their hardness and wear resistance. This allows the razor wire to maintain its cutting ability and stability over extended periods of use without dulling or damage. Whether faced with high pressure, high temperature or frequent use, razor wire can withstand the test and maintain long-lasting durability.

Part III: Wide application of razor wire in security field and other fields

Safety protection: Razor wire is widely used in the field of safety protection to protect the safety of private residences, commercial buildings and public places. Its anti-corrosion performance and durability enable it to withstand severe weather and external erosion, providing reliable safety protection.

Agriculture and horticulture: Razor nets are commonly used in agriculture and horticulture to build fences, fences and livestock fences. Its corrosion resistance and durability allow it to withstand the challenges of outdoor environments, providing reliable protection and support.

Construction and Decoration: Razor wire is also widely used in the field of construction and decoration for decoration, isolation and decoration of indoor and outdoor. Its corrosion-resistant properties and durability make it ideal as a building material, adding safety and aesthetics to buildings.

.jpg)

.png)