Over the years, China wire mesh manufacturers have made significant strides in improving product quality and efficiency through the adoption of advanced technologies. This article explores how China's wire mesh manufacturers are leveraging technology to enhance the quality of their products, meet international standards, and remain competitive in the global market.

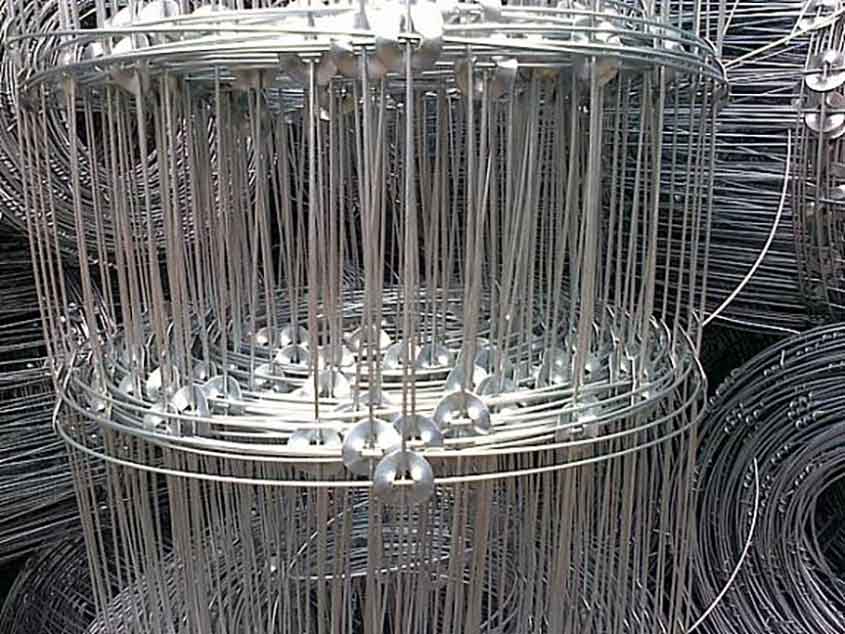

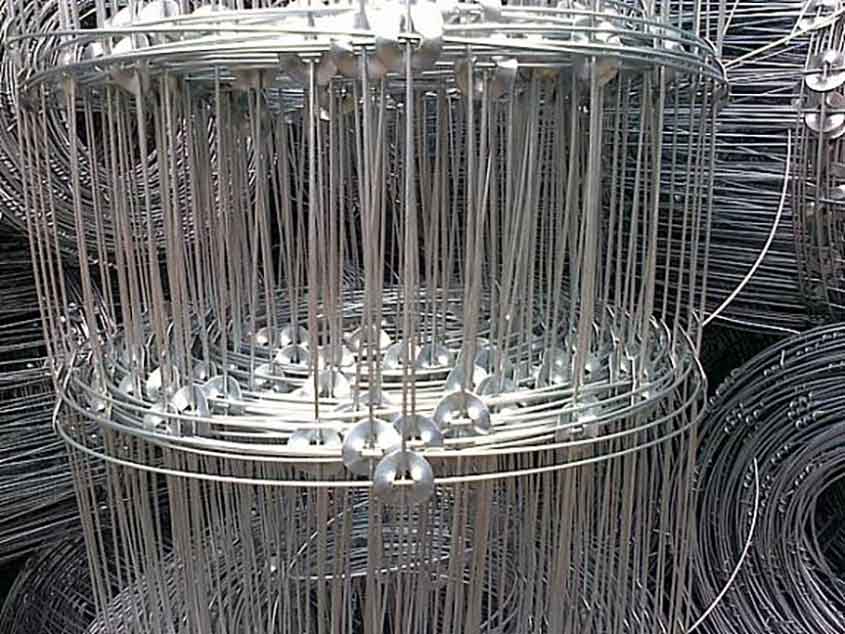

Automated Production Processes:

One of the key areas where Chinese wire mesh manufacturers have embraced technology is in automating production processes. Automation allows for greater precision, consistency, and efficiency in manufacturing wire mesh products. Advanced machines and robots are employed to handle tasks such as wire drawing, mesh weaving, and welding. This level of automation minimizes human errors, ensures uniformity in product quality, and boosts overall production capacity.

Digital Quality Control:

Technology-driven quality control systems have become an integral part of modern wire mesh manufacturing in China. Through the use of digital sensors and inspection equipment, manufacturers can monitor the quality of raw materials, detect defects, and analyze mesh properties during production. Real-time data analysis enables prompt adjustments to ensure that products meet stringent quality standards. This attention to detail has bolstered the reputation of Chinese wire mesh products for their reliability and durability.

Material Innovations:

Innovations in wire materials have been another focus for Chinese manufacturers seeking to enhance the quality of wire mesh products. The adoption of high-grade stainless steel wire and other specialized materials with improved tensile strength and corrosion resistance has resulted in wire mesh that can withstand challenging environmental conditions and demanding applications.

.jpg)

.png)