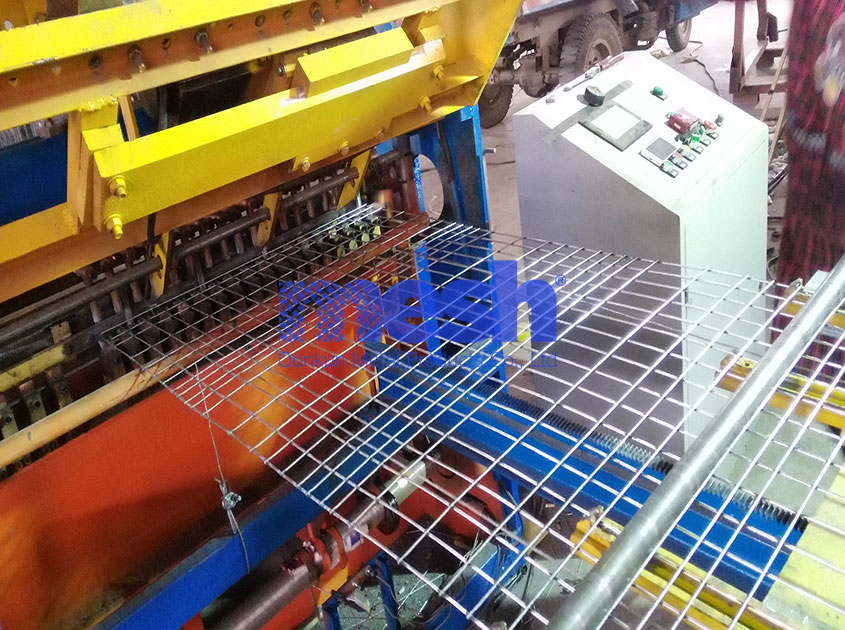

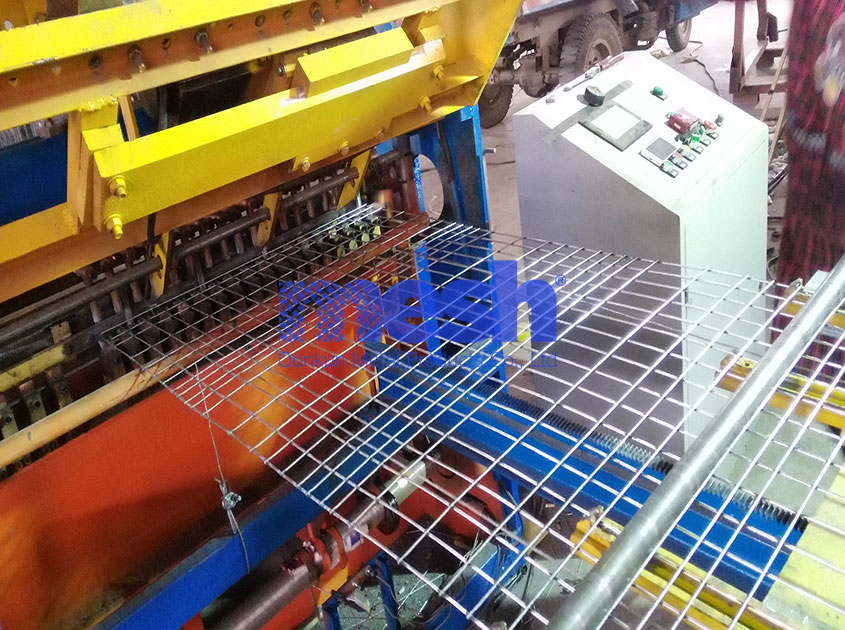

Welded wire mesh rolls are versatile and essential components across a spectrum of industries, from construction to agriculture. Understanding the intricacies of their specifications is crucial for making informed decisions and achieving optimal results. In this comprehensive guide, we embark on a journey to unveil the key product specifications of welded wire mesh rolls, empowering you with the knowledge to navigate their perse applications.

Wire Gauge and Diameter:

The wire gauge, measured in terms of its diameter, is a critical specification that impacts the strength and durability of the welded wire mesh. Thicker wires offer increased structural integrity, making them suitable for heavy-duty applications such as industrial fencing or reinforcement in concrete structures. Thinner wires, on the other hand, find utility in lighter applications like garden fencing or poultry enclosures.

Mesh Size and Openings:

The mesh size refers to the distance between adjacent wire intersections. Smaller mesh sizes provide finer and more intricate patterns, making them ideal for applications requiring greater detail, such as sifting or filtration. Larger mesh sizes offer enhanced visibility and airflow, making them suitable for animal enclosures or general fencing.

As we unveil the specifications of welded wire mesh rolls, we gain a deeper appreciation for their significance in perse industries. Their wire gauge, mesh size, material, and dimensions converge to determine their suitability for specific applications. By understanding these specifications, you empower yourself to make informed choices, harnessing the versatility and functionality of welded wire mesh rolls to meet your project requirements with precision and confidence.

.jpg)

.png)