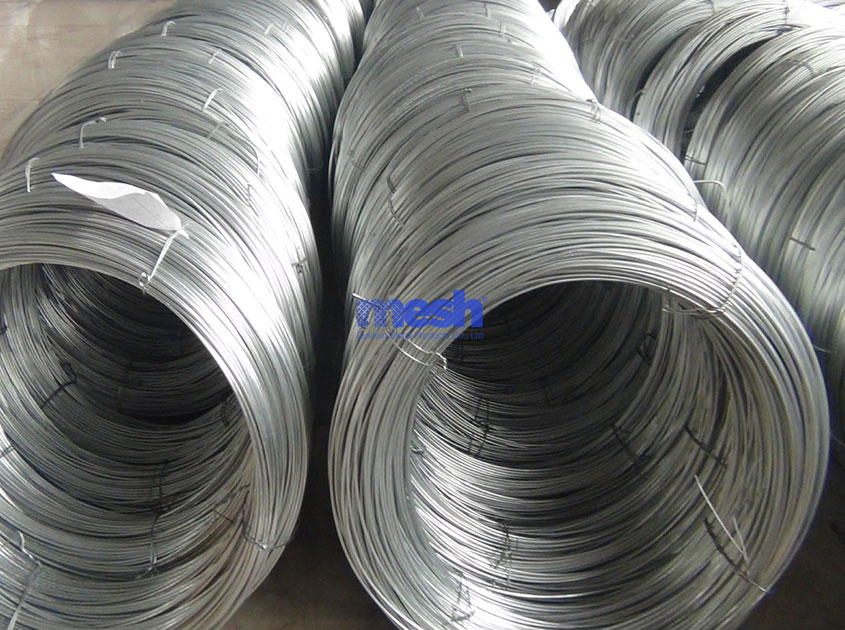

As a common and versatile metal material, Galvanized Iron Wire has a wide range of applications in various fields. However, when choosing the right Galvanized Iron Wire, it is crucial to have a deep understanding of its technical details.

Effect of Zinc Layer Thickness: Corrosion Resistance and Durability

The thickness of the zinc layer of Galvanized Iron Wire is one of the important factors in determining its corrosion resistance and durability. The thicker zinc layer provides greater corrosion protection against rain, oxygen and chemicals, extending the life of the Galvanized Iron Wire. In different application scenarios, it is very important to choose the appropriate zinc layer thickness according to the harshness of the environment.

Choice of Wire Diameter: A Balance of Strength and Function

Wire gauge refers to the diameter of the metal wire in Galvanized Iron Wire. The choice of wire diameter is not only related to strength, but also related to the realization of function. Thicker wire diameters provide higher load-bearing capacity and are suitable for occasions that require strength; while thinner wire diameters are more flexible and suitable for some applications that require shape shaping. According to project requirements, it is very important to find the balance between wire diameter and function.

Environmental awareness should also be taken into consideration when purchasing Galvanized Iron Wire. Choose a zinc layer treatment process that meets environmental protection standards to ensure that the impact of the production process on the environment is minimized, thereby making the application of Galvanized Iron Wire more sustainable and socially valuable. By understanding the technical details of Galvanized Iron Wire, you can better choose the right material to meet different project needs.

.jpg)

.png)