In the realm of metals, the battle for supremacy between galvanized iron wire and traditional steel rages on. Each contender boasts its own set of attributes, catering to a perse range of industries and applications. This article pes into the epic showdown between galvanized iron wire and traditional steel, exploring their merits and helping you determine which reigns supreme in the world of metallurgy.

The Galvanized Transformation

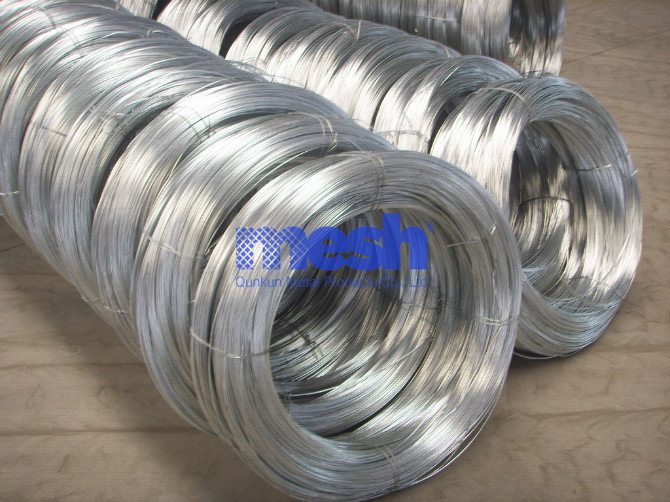

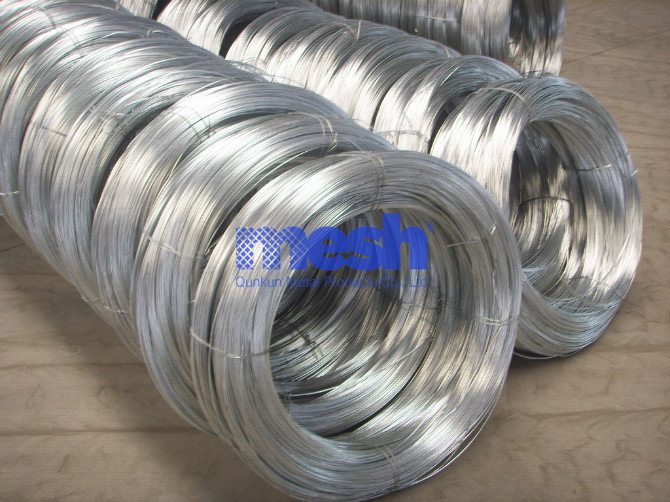

Galvanized Iron Wire: Galvanized iron wire undergoes a transformative process that sets it apart. By subjecting iron wire to a bath of molten zinc, a protective zinc coating is formed, creating a barrier against corrosion. This process, known as galvanization, infuses the wire with exceptional rust resistance, making it ideal for outdoor applications and environments prone to moisture.

Traditional Steel: Traditional steel, while inherently strong, lacks the added protection of a zinc coating. Without proper treatment, steel is vulnerable to rust and corrosion, especially in humid or corrosive environments.

Battle Against Rust

Galvanized Iron Wire: The zinc coating on galvanized iron wire serves as a valiant protector against rust. Even if the coating is scratched or chipped, the zinc's sacrificial protection mechanism ensures that the underlying iron remains shielded, preventing rust from taking hold.

Traditional Steel: Traditional steel, unless coated with anti-corrosion materials, is susceptible to rust. Exposure to moisture and air over time leads to the formation of iron oxide, weakening the structural integrity of the material.

Conclusion

In the grand showdown between galvanized iron wire and traditional steel, the ultimate winner depends on the context. Galvanized iron wire's resilience against rust and corrosion grants it an edge in durability and low-maintenance applications. On the other hand, traditional steel's versatility in finishes and lower upfront cost can be advantageous for certain projects. As you consider the attributes that align with your priorities—whether it's longevity, aesthetics, or cost-efficiency—you'll be equipped to make a decision that positions your project for success in the ever-evolving world of metallurgy.

.jpg)

.png)