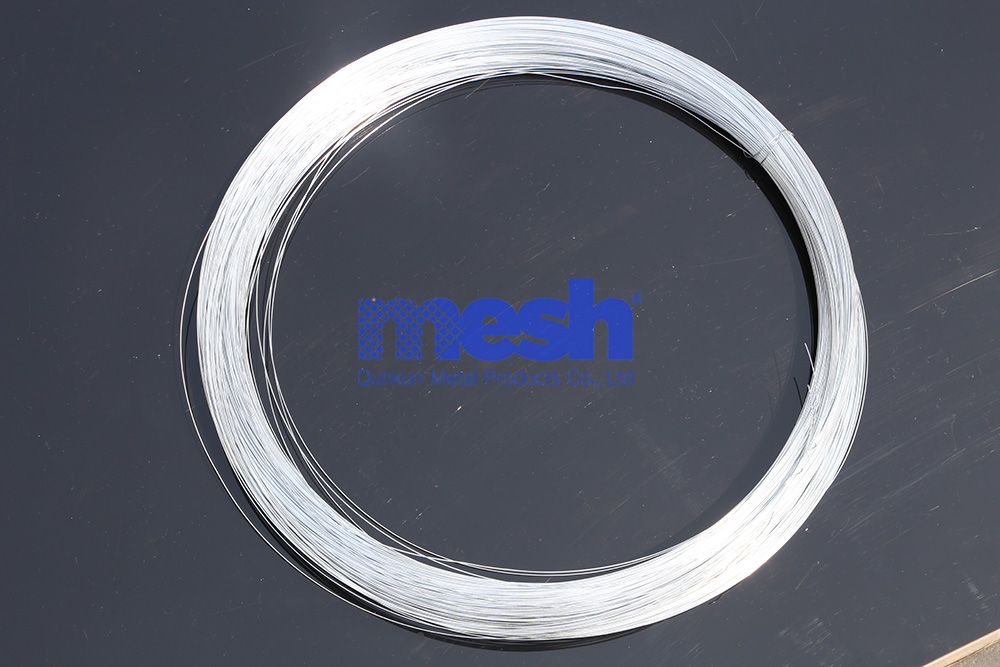

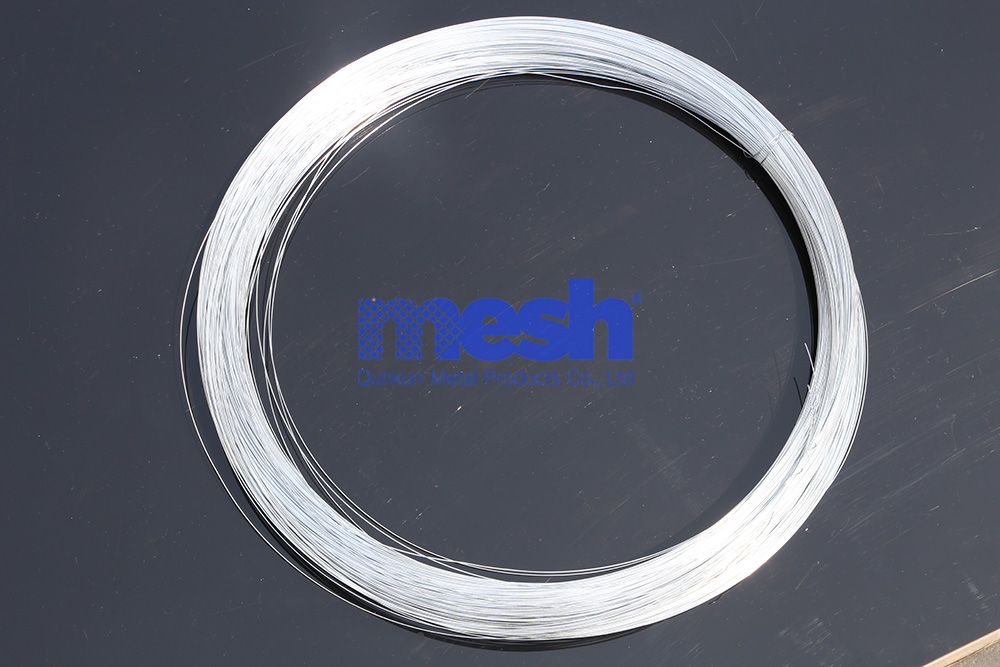

In the world of construction, industrial applications, and everyday objects, galvanized iron wire stands as a testament to the marriage of strength, durability, and corrosion resistance. Yet, behind its unassuming appearance lies a complex manufacturing process that transforms simple iron wire into a material that defies the test of time. In this article, we embark on a journey to explore the intricate and fascinating journey of creating galvanized iron wire.

From Raw Material to Metallurgical Marvel

The journey of galvanized iron wire begins with a humble raw material: iron wire. This wire is meticulously cleaned and processed to remove any impurities, ensuring the resulting galvanized wire is of the highest quality. The transformation from raw material to finished product involves a series of carefully orchestrated steps that culminate in a metallurgical marvel.

Wire Drawing: Shaping the Foundation

The process begins with wire drawing, where the cleaned iron wire is passed through a series of progressively smaller dies to reduce its diameter. This drawing process not only shapes the wire but also improves its tensile strength and surface finish. The resulting wire serves as the foundation for the galvanization process.

Pickling: Preparing for Galvanization

Before the galvanization can commence, the wire undergoes pickling. This involves immersing the wire in a solution that removes any residual oxides or contaminants, ensuring a clean surface for the galvanizing process. Proper pickling is crucial to achieving a strong and uniform galvanized coating.

.jpg)

.png)