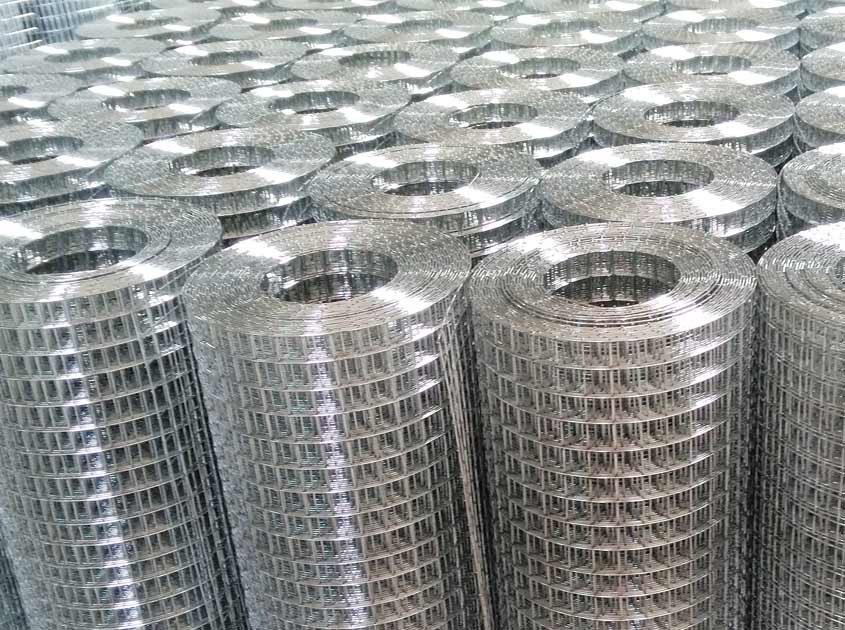

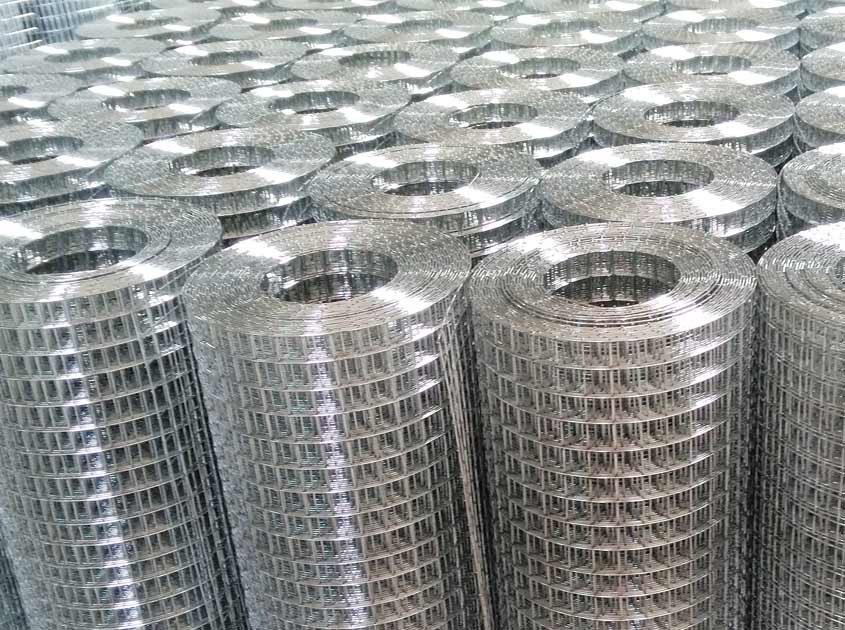

Galvanized wire mesh is a material widely used in wire mesh fencing that provides superior durability and corrosion protection by coating the surface of the wire with zinc. The production process of galvanized wire mesh is very critical, which involves steps such as cleaning, hot-dip galvanizing and subsequent processing of steel wires. These steps ensure even distribution and strong adhesion of the galvanized layer, thereby increasing the life and reliability of the wire mesh fence.

In fencing applications, galvanized wire mesh offers many advantages. First, it has excellent weather resistance, resisting corrosion and damage in a variety of climate conditions. Secondly, the surface of galvanized wire mesh is smooth and difficult to stab people or animals, providing higher safety. In addition, galvanized wire mesh also has low maintenance costs and is economical for long-term use.

To choose the right galvanized wire mesh, there are different specifications, mesh sizes, and wire diameters to consider. This depends on the purpose of the fence and the level of security required. Whether it is used for safety protection in industrial areas or for livestock and poultry fencing in agriculture, galvanized wire mesh is a reliable choice.

In short, galvanized wire mesh is a material that is widely used in the field of wire mesh fencing. Galvanized wire mesh ensures the reliability and safety of your fence by providing durability and corrosion protection. Whether you are protecting property or ensuring the safety of people and animals, choosing galvanized wire mesh is a wise decision.

.jpg)

.png)