2025-01-21

Production process and quality control of stainless steel wire mesh

As a precision manufacturing product, the process selection and quality control in the production of stainless steel wire mesh directly affect the performance and application effect of the final product. This article will provide a detailed introduction to the production process of stainless steel wire mesh and explore how to implement effective quality control measures to ensure the stability and reliability of product quality.

Production process flow

Raw material preparation: High quality stainless steel wire is selected as the raw material, and suitable grades (such as 304, 316, etc.) are chosen according to the needs to ensure the corrosion resistance and mechanical properties of the product.

Wire drawing treatment: Stainless steel wire is cold drawn by a wire drawing machine to form fine wires of the desired diameter. This process requires strict control of the drawing speed and temperature to avoid excessive internal stress in the material causing fracture.

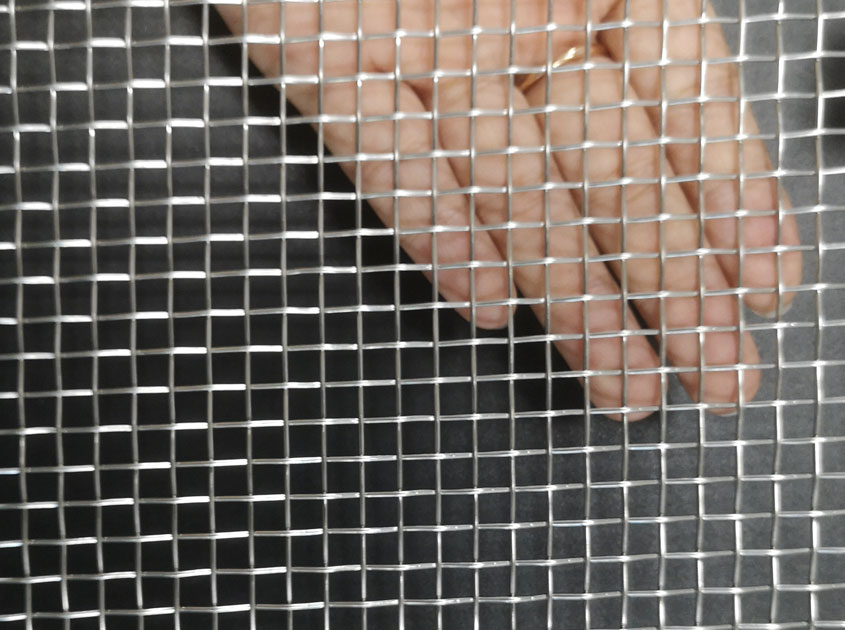

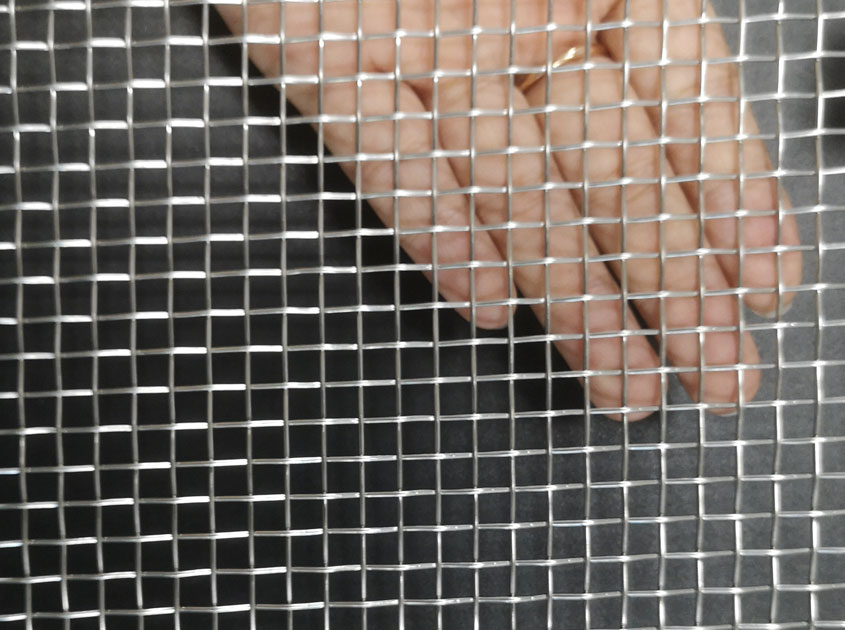

Weaving molding: Using mechanical or manual methods, stainless steel filaments are woven according to specific patterns or specifications to form a mesh structure. Weaving technology directly affects the density, strength, and appearance of products.

Surface treatment: Polish, electroplate or passivate the woven stainless steel wire mesh as needed to enhance its surface smoothness and further improve its corrosion resistance.

Inspection and packaging: After completing all production steps, strict quality inspection is carried out, including size measurement, tensile testing, corrosion resistance testing, etc., to ensure that the product meets the standards. Finally, pack properly to prevent damage during transportation.

Quality control measures

Raw material inspection: All raw materials must undergo chemical composition analysis and mechanical property testing before use to ensure that the material meets the requirements.

Process monitoring: Multiple quality control points are set up during the production process to monitor key parameters such as wire drawing diameter and weaving density in real-time, and adjust process parameters in a timely manner.

Finished product inspection: Advanced testing equipment is used to comprehensively inspect finished products, including but not limited to appearance inspection, mechanical performance testing, and environmental adaptability testing.

Continuous improvement: Establish a quality feedback mechanism, collect customer feedback, continuously optimize production processes and quality control procedures, and improve product quality.

Through the above production process and strict quality control measures, the production of stainless steel wire mesh can not only ensure the high quality of products, but also meet the special requirements of different industries for material properties, providing solid guarantees for users' practical applications.

prev:Analysis of the Various Applications and Advantages of Stainless Steel Wire Mesh

next:The Ultimate Guide to Welded Wire Mesh Rolls: A Versatile and Durable Solution

.jpg)

.png)