The common terms for screens are as follows:

Crack: Longitudinal cracks, cracks, cracks in the appearance of steel wire.

Cracking (stinging): The outer surface of the wire is cracked by the visible horizontal strip, and the tongue or other shape of the thorn appears.

Layering: the longitudinal direction of the wire or the splitting of the length

Scarred (spotted): yellow yttrium oxide on white steel surface, white lime 疤

Pull marks: The distinct small grooves or ribs that exist in the longitudinal direction of the steel wire. The slightness only makes the appearance of the wire appear not only clean and bright.

Folding: The outer surface of the wire is biased toward the length of the metal stack. Often linear, but also curved or zigzag. When the metallographic examination is carried out, there are iron oxide dopants and decarburized layers in the fold.

Concave: Partially concave on the outer surface of the wire.

Corrosion: The appearance of the steel wire shows a partial and overall oxidation scene.

Pitting: A point-like or sheet-like scattered pit that appears when the steel wire is severely oxidized.

Bamboo section: The wire has a periodic thickness unevenness along the longitudinal direction, and its shape resembles a bamboo knot.

Spiral pattern: The threaded roll of the steel surface during the straightening process.

Oxide: The appearance of the steel wire is oxidized when it comes into contact with the high temperature oxidation furnace gas to form a solid, fragile oxide.

Oxide film: The outer surface of the steel wire forms a thin layer of dense oxide. This oxide is generally not easily broken, and is only partially peeled off when it is subjected to bending or deformation.

Oxidation color: The outer surface of the steel wire forms a very thin layer of oxide attached to the outer surface of the steel wire under the premise of bright heat treatment.

Decarburization layer: In the region where the carbon content of the surface layer is reduced due to the effect of the gas medium and the carbon layer of the steel layer when the steel wire is heated, the phenomenon that the surface carbon amount is lowered is called decarburization.

Graphite carbon: Partial or all-case carbon in steel is precipitated in free form. This carbon in free form is pyrocarbon.

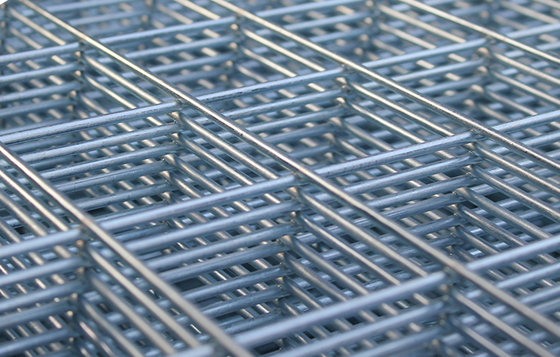

Creases: Partially folded on the mesh surface to form a mark that does not recover.

Broken hole: There are concentrated warp or weft multiple broken wires on the mesh surface.

Corrosion: Erosion on the mesh surface, rust spots: green, brown or small-colored mottled on the mesh surface.

Broken wire: The warp or weft thread on the mesh surface should be disconnected.

Mosquito mouth: the wire is looped, twisted, and emptied out of the mesh.

Top buckle: bad warp joints, top out the mesh surface.

Shrinking: The latitude is partially cubic meters curved and the mesh is deformed.

Wire: Two or more wires are woven together in parallel.

Jumping wire (jumping): Interlaced errors in warp or weft.

Pine: loose warping of a single warp or weft.

Weaving of debris: foreign matter is woven inside the net.

Cloud weave: The weft is too soft or the soft and hard is uneven to form a random cloud network.

Drum kit: The mesh surface is bulging.

Double line: Stacked by warp or weft.

Large pores: The regularity of the mesh surface is uneven.

Dense file: The single mesh of the mesh is too large or too small.

Pine edge: The edge of the net is a wave-like bulge.

Wire diameter - the diameter of the wire;

Warp--all longitudinal braided lines;

Weft - the transverse braided line of everything;

Number of meshes - the number of cells in the length of -1 inch;

Density - the number of meshes in the length of -1 cm

Mesh - the spacing between two warp threads or two weft threads

Public service--the vertical interval between the warp and the public service line at the heald (MM)

Male line - the connection of the chestnut (roller) before and after

Shanggong--the meridian of the comprehensive flat heald is higher than the public service line

Under the public service - below the public service line called the public service

Zero public service - coincidence with the public service line called zero public service

Comprehensive angle - the interval between the upper and lower healds after the heald of the heald frame

Flat angle--(variation angle)--Generally, the spacing between steel slabs and long latitudes

.jpg)

.png)