The temperature of

nickel wire mesh, the temperature of molten metal pouring, the indenter, and the vacuum degree during casting all have an effect on the surface roughness of nickel wire mesh, especially the mold temperature and the pouring temperature.

的 The relationship between the temperature of nickel wire mesh and the temperature of molten metal pouring and the surface roughness of nickel wire mesh. With the increase of the temperature and the pouring temperature of the metal liquid, the filling performance of the metal liquid improves, the depth of penetration into the surface pores increases, and the surface roughness of the nickel mesh increases.

The thermal conductivity is small. After the use of stainless steel, the molten metal is cooled slowly in the pouring type. The nickel mesh produced has coarse grains. The inter-grain grooves will roughen the surface of the nickel mesh. The depth of such grain boundary grooves is even Will reach 7μm.

The alloy should be modified, and fillers such as zircon, which have better thermal conductivity, should be used to increase the cooling speed of the nickel wire mesh, make the surface layer grains smaller, and reduce the surface roughness.

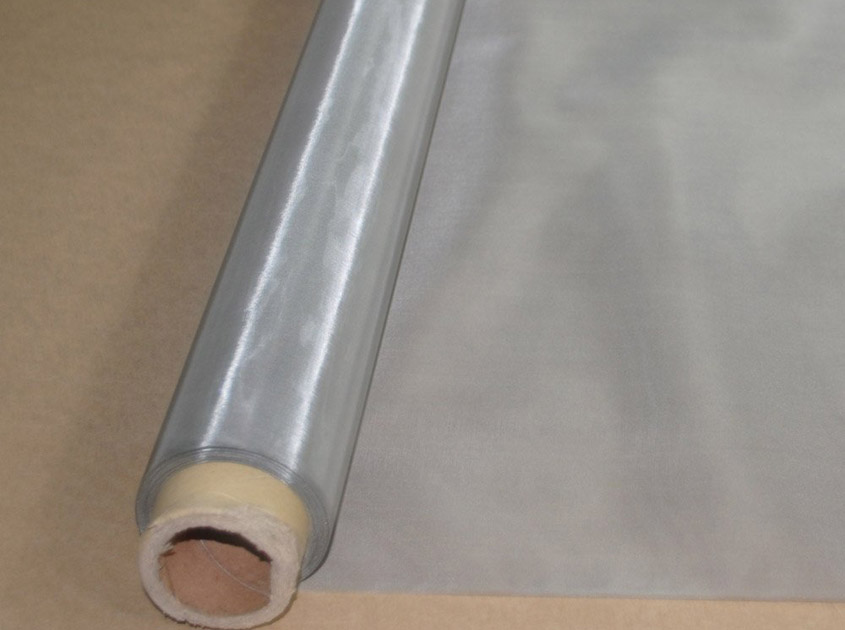

Nickel wire mesh is a kind of parts used in industrial production. It is used in filtration machinery of batteries, chemical industry, mining, telecommunications, alkali production, acid production, hydrogen production industry and scientific research departments.

.jpg)

.png)