2019-12-31

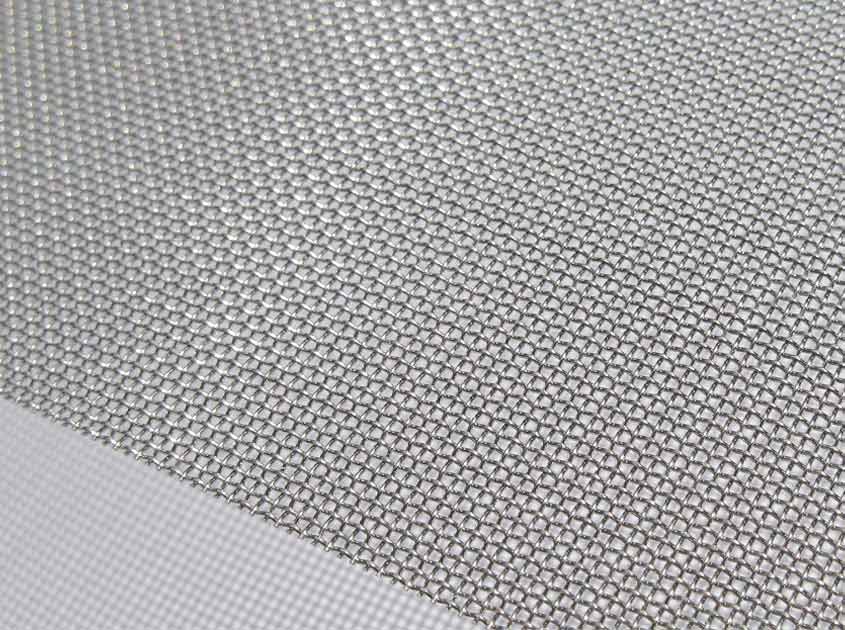

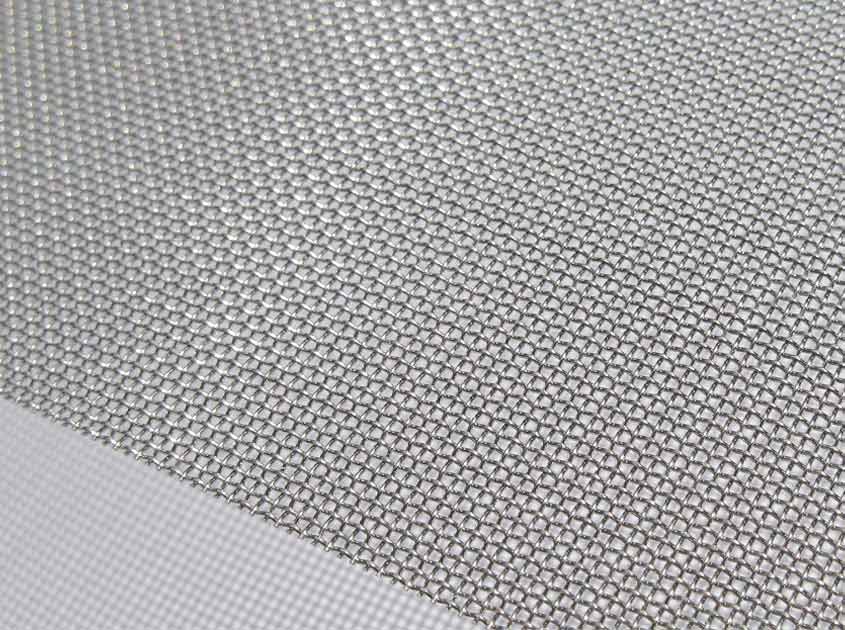

The sheet has excellent anti-corrosion performance and is not easy to rust. Stainless steel has unique strength, high abrasion resistance, superior anti-corrosion performance and not easy to rust. Widely used in chemical industry, mechanical and electrical industry, environmental protection industry, home appliance industry and home decoration, finishing industry.

The application development prospect of stainless steel is more and more broad, but the application development of stainless steel largely determines the development degree of its surface treatment technology. Commonly used stainless steel mesh surface treatment technology has the following treatment methods: First, the stainless steel surface mirror bright treatment method: Surface color treatment: stainless steel coloring not only gives stainless steel products a variety of colors, increase product variety, but also improve product wear resistance and Corrosive. Second, the surface natural whitening treatment: stainless steel in the processing process, after rolling, edging, welding, or artificial surface fire roasting and heating treatment, resulting in black oxide scale. At present, there are two main methods for treating scale: 1. Chemical method: use a non-pollution pickling passivation paste and non-toxic cleaning solution with inorganic additives at room temperature for dipping. So as to achieve the purpose of whitening stainless steel. After processing, it basically looks a dull color. This method is more suitable for large and complex products. 2. Sand blasting (pellet) method: The method of spraying micro glass beads is mainly used to remove the black oxide scale on the surface. Three, stainless steel coloring methods are as follows: A brief overview of various methods are as follows: 1. Chemical coloring method: the color of the film formed by electrochemical oxidation in a specific solution. 2. Learn the oxidation coloring method: It is the color of the film formed by chemical oxidation in a specific solution. There are dichromate method, mixed sodium salt method, sulfuration method, acid oxidation method and alkaline oxidation method. Generally, the "Inco method" (INCO) is used more, but if you want to ensure the uniform color of a batch of products, you must use a reference electrode to control. 3. Warm oxidation coloring method: It is to immerse the workpiece in a certain molten salt and keep it at a certain process parameter, so that the workpiece forms an oxide film with a certain thickness and presents various colors. 4. Sub-deposited oxide coloring chemical method: It is to place the stainless steel workpiece in a vacuum coating machine for vacuum evaporation plating. For example: titanium-plated watch cases and watch bands are usually golden yellow. This method is suitable for high-volume product processing. Because of the large investment and high cost, small batches are not cost effective. 5, phase cracking coloring method: more complex, less applied in industry.

prev:the anti-theft screw of the fence mesh

next:Building mesh, square eye mesh, square hole mesh, anti-cracking mesh

.jpg)

.png)