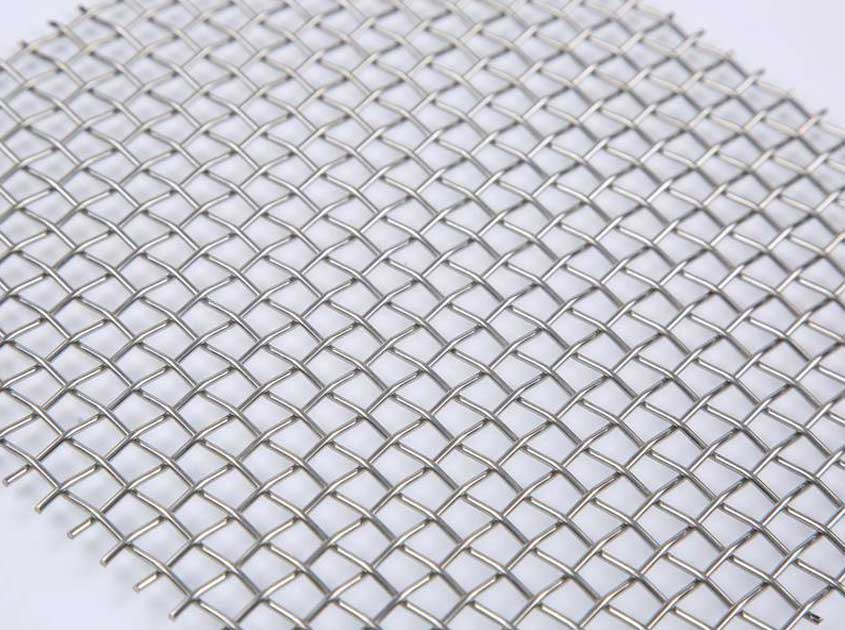

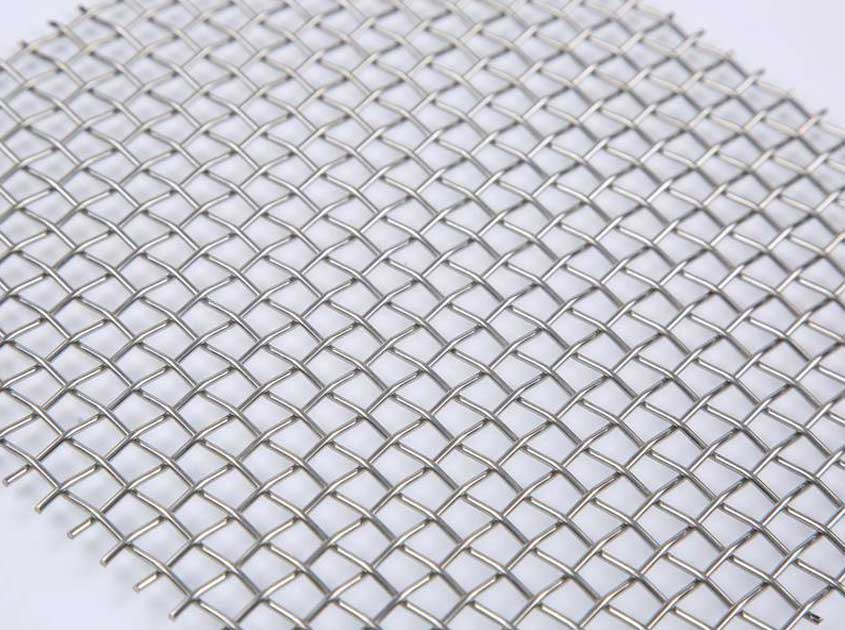

Stainless steel mesh is widely used in screening, filtering, and protective decoration, and is applicable in the mining, petroleum, chemical, food, pharmaceutical, machinery manufacturing, building decoration, electronics, aerospace and other industries.

When using it, it is difficult to think that the particles will be too large and the screen will be blocked. How to solve this situation?

Solution to particle blockage.

Suggestions for resolving the blockage of the screen: Adjust the screen tension and reasonable tension of the stainless steel screen to make the screen and the supporting beam generate a slight secondary vibration, thereby effectively reducing the occurrence of screen plugging. The tension hook is made into a constant tension mechanism, that is, a spring is installed on the tension bolt! This solves the problem of removing the blockage of stainless steel mesh particles.

It is inevitable to weld and cut the stainless steel mesh structure in the use of the stainless steel mesh. Because of the characteristics of the stainless steel mesh itself, the welding and cutting of the stainless steel mesh and the ordinary carbon steel have their special characteristics.

For example, the thermal expansion coefficient of austenitic stainless steel mesh is 1.5 times that of low carbon steel and high chromium series stainless steel; the thermal conductivity is about 1/3 that of low carbon steel, and the thermal conductivity of high chromium series stainless steel is about 1 / 2; Specific resistance is more than 4 times that of low carbon steel, and high chromium series stainless steel mesh is 3 times that of low carbon steel.

.jpg)

.png)