304,316 filter bags are commonly used for liquid filtration, which refers to bags made of regular arranged nets cut and produced from stainless steel wires or plates and other stainless steel materials.

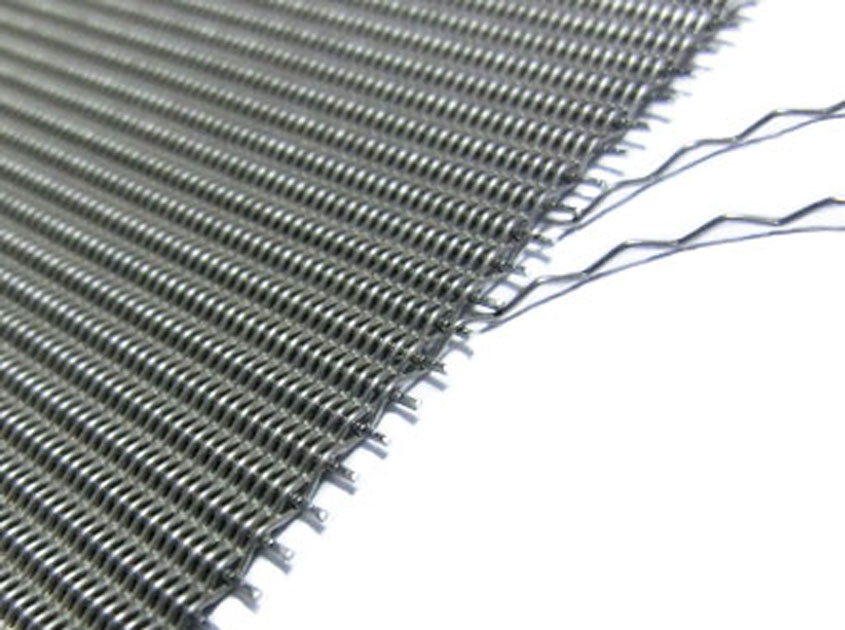

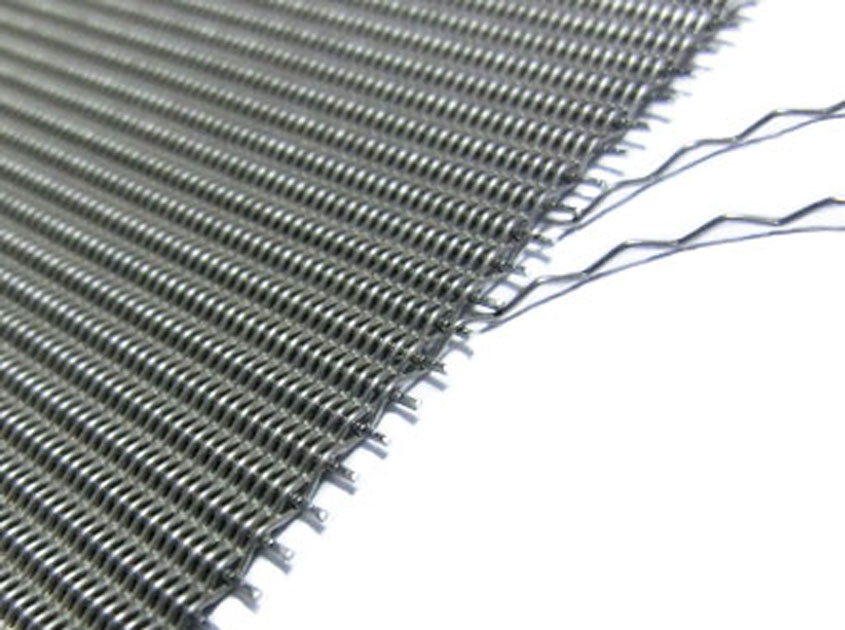

The common materials used for liquid filtration are 304 and 316L. The main difference between the two is the content of chromium and nickel. The stainless steel filter bag is used with a stainless steel ring mouth, rolled into a wavy mesh shape, and overlapped with each other at the correct angle. Made.

Multi-layer folding and expansion is an arrangement with different densities and pore diameters from coarse to fine. When the object passes through, it changes the flow direction multiple times to increase its efficiency. The stainless steel mesh filter bag has high strength and will not be deformed due to pressure changes. The monofilament weave constitutes a smooth surface, which is easy to clean and can be used repeatedly. It is also suitable for some liquid filtration with high impurity content. Low initial resistance and strong fire resistance.

Long service life, economical and reliable, low operating cost; lightweight plate structure, easy and safe to replace, convenient for users to operate by themselves; there are galvanized frames and aluminum alloy frames to choose from; non-standard size equipment can be customized according to user needs.

Coatings paints and inks: latex paints, paint materials and solvent filtration, printing inks, printing ink filtration. Other industries: various liquid purification and filtration in fine chemical industry, petrochemical industry, electronics, textile, printing and dyeing, papermaking and other industries.

.jpg)

.png)