2018-04-02

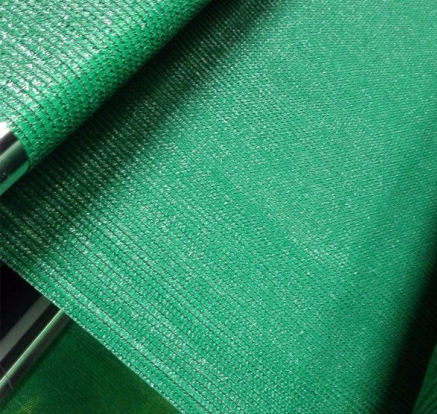

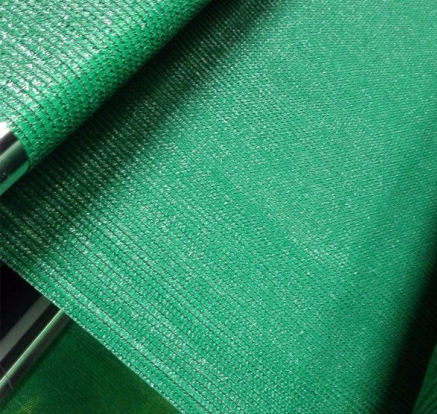

With the continuous development of production technology, there are more and more types of shade nets, which meet the different coverage requirements of everyone. Today we introduce the common flat shade net production process:

1. The purchase of raw materials: raw materials are divided into new materials and renewable materials, new materials, good color, light weight, good feel, long service life, generally more than 5 years, high cost. Renewable materials, poor gloss, poor texture, short service life generally between 3 months and 1 year, the cost is low.

2. Drawing production: drawing is divided into round wire and flat wire. The production process is as follows: batch mixing, drying and melting, extrusion, cooling, splitting, stretching, shaping.

3. Webbing: According to the sample selection process and threading method, the grammage is adjusted in real time according to the weight of the sample until it matches the sample. Mass production.

4. Qualification: The staff of the workshop inspection department is responsible for checking whether the net cloth is qualified.

5. Packaging products: according to customer requirements for packaging labeling. When the customer does not require it, the volume must not exceed 50 meters.

The production process of flat wire shade nets is mainly divided into these five steps. During production operations, it is necessary to pay attention to the correct method, and the relevant details must be clearly understood, so that the quality of flat wire shade nets can be better protected.

Abby

M: +86 180 3191 8950

W: www.qunkun.net

E: abby@qunkunmetal.com/qun@qunkun.net

prev:The large function of Shade net

next:Production process of Flat wire shade net

.jpg)

.png)