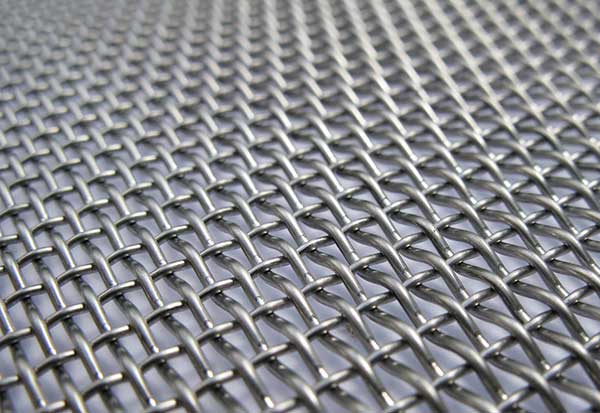

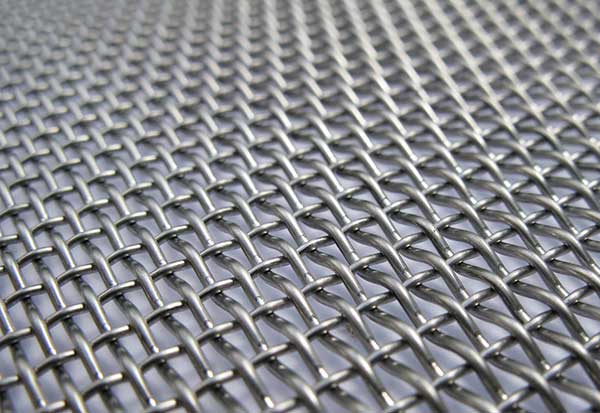

Stainless steel mesh is currently the most common, widely used, and largest wire mesh in the market. What people usually call stainless steel mesh mainly refers to stainless steel woven mesh.

First, stainless steel knowledge:

Before talking about stainless steel woven mesh, let's briefly introduce the relevant knowledge of stainless steel: It has high chemical stability in the air, as well as in water, seawater or various acid, alkali, salt and other aqueous solutions, although it is stored for a long time. Steel that is placed in it, but still does not oxidize, rust or corrode, is commonly referred to as stainless steel.

Stainless steel is a large series of special steels, which play an irreplaceable role in chemical, petroleum, electronics, national defense and other industries. At present, the most widely used metal woven mesh should be stainless steel wire. Therefore, we need to understand the influence of several main elements in stainless steel on the properties of stainless steel:

1. Chromium (Cr) is the main factor determining the corrosion resistance of stainless steel. Metal corrosion is pided into chemical corrosion and non-chemical corrosion. At high temperature, the metal directly reacts with oxygen in the air to generate oxides (rust), which is chemical corrosion; at normal temperature, this corrosion is non-chemical corrosion. Chromium is very easy to form a dense passivation film in the oxidizing medium. This layer of passivation film is stable and complete, firmly bonded with the base metal, and completely separates the base from the medium, thereby improving the corrosion resistance of the alloy. 11% is the minimum limit of chromium content in stainless steel, and steel containing less than 11% chromium can generally not be called stainless steel.

2. Nickel (Ni) is an excellent corrosion-resistant material and is the main element that forms austenite in steel. After adding nickel to stainless steel, the structure changes obviously. When the content of nickel in stainless steel increases, austenite will increase, and the corrosion resistance, high temperature resistance and processability of stainless steel will be enhanced, thereby improving the cold working process performance of steel. Therefore, stainless steel with higher nickel content is more suitable for drawing filaments and microwires.

3. Molybdenum (Mo) can improve the corrosion resistance of stainless steel. Adding molybdenum to stainless steel can further passivate the surface of stainless steel, thereby further improving the corrosion resistance of stainless steel. Molybdenum cannot form precipitation and precipitate molybdenum in stainless steel, thereby improving the tensile strength of stainless steel.

4. Carbon (C) is represented by "0" in stainless steel. A "0" means the carbon content is less than or equal to 0.09%; "00" means the carbon content is less than or equal to 0.03%. Increased carbon content reduces the corrosion resistance of stainless steel, but increases the hardness of stainless steel.

There are many types of stainless steel grades, including austenite, ferrite, martensite and duplex stainless steel. Because austenite has the best comprehensive properties, is non-magnetic and has high toughness and plasticity, it is used for wire mesh processing. The best stainless steel wire is austenitic stainless steel. Austenitic stainless steel has 302 (1Cr8Ni9), 304 (0Cr18Ni9), 304L (00Cr19Ni10), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 321 (0Cr18Ni9Ti) and other grades. Judging from the content of chromium (Cr), nickel (Ni) and molybdenum (Mo), 304 and 304L wire rods have good comprehensive performance and corrosion resistance, and are currently the most used wire rods for stainless steel mesh; 316 and 316L contain high nickel, and It contains molybdenum, which is most suitable for the drawing of microfilaments, and has good corrosion resistance and high temperature resistance.

In addition, it is necessary to remind friends of wire mesh processing that stainless steel wire has a time effect. After it is placed at room temperature for a period of time, the processing deformation stress is reduced, so it is better to use stainless steel wire after a period of time as a woven mesh.

.jpg)

.png)