2018-01-15

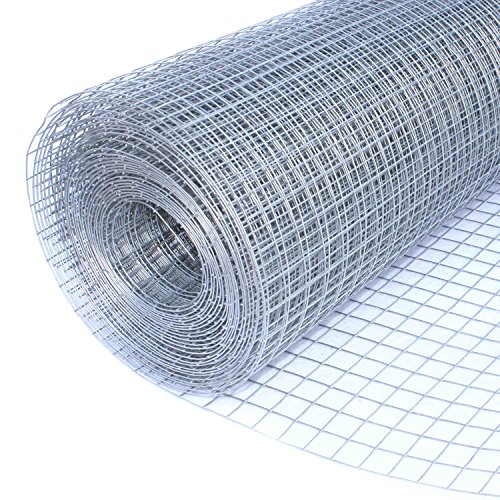

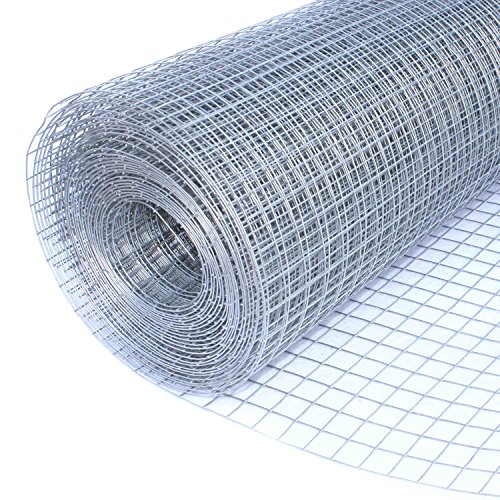

Welded wire mesh has been used in modern life and has become an important part of life. High strength, strong anti-aging and anti-acid corrosion ability are very important. It has a collection of many materials of a nature, and the price is often more affordable. Therefore, many businesses are also gradually moving into this industry. Galvanized welded wire mesh can be divided into two categories: hot dip galvanized and cold galvanized.

From the appearance point of view two kinds of galvanized welded wire mesh also has a more obvious difference, the general galvanized is the appearance of cold galvanized are relatively smooth and bright. If the use of color passivation process, then the surface of the plating layer will mainly appear yellowish green, in the sun will show a colorful color. If using a white passivated process, the surface of the plating will appear white or greenish white. After this process after the plating layer in the sun will usually show a colorful color.

Galvanized welded wire mesh typically has a thickness of five to fifteen microns, whereas hot-dip zinc plating is typically over thirty-five microns and sometimes up to two hundred microns. Under normal circumstances, the coverage of hot-dip galvanized can be better, between the coating is also relatively dense, almost no organic inclusion. Zinc can resist some of the natural corrosion, so for mechanical and electrochemical protection.

Therefore, the existence of this layer of zinc can be well regarded as a protective film, even after receiving the broken outside is the first consumption of zinc, zinc consumption until the end until the consumption of iron will begin.

prev: Teach you to quickly and accurately distinguish between large and small wire welded wire mesh

next:Why cold galvanized wire mesh can be used as heat insulating material

.jpg)

.png)