Ocean engineering is a field with extremely high requirements on materials and structures, and welded wire mesh panels show excellent performance in marine environments due to their excellent corrosion resistance and reliability. This article will deeply discuss the excellent performance of welded mesh panels in marine engineering, revealing its important role and advantages in projects such as marine structures, coastal protection and marine energy.

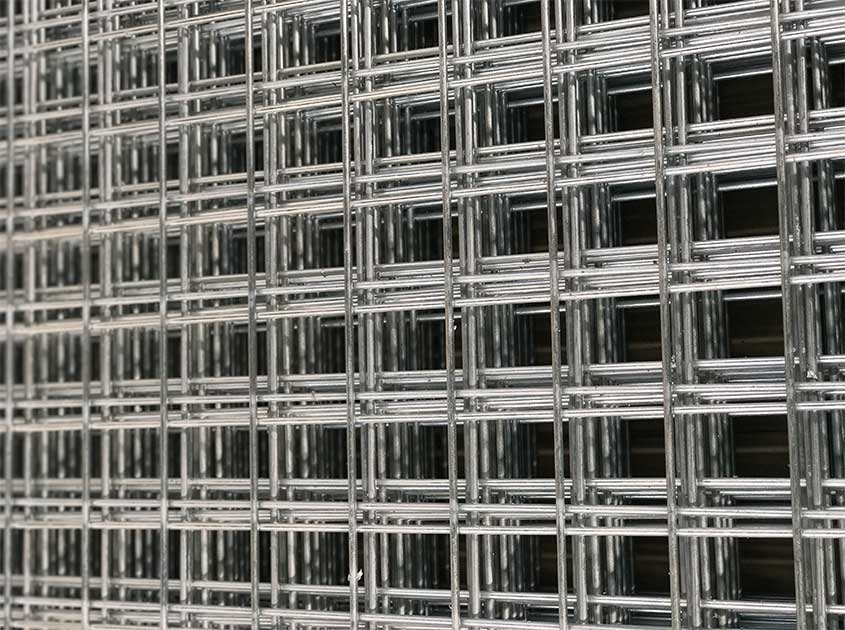

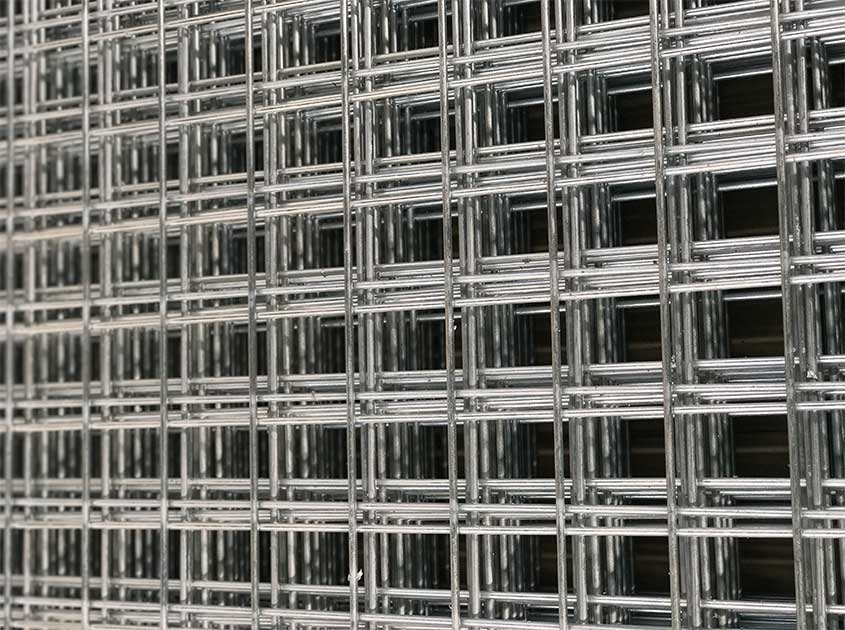

Corrosion resistance and oxidation resistance of welded wire mesh panel:

The welded mesh panels are made of high-quality stainless steel or galvanized, which has excellent corrosion resistance and oxidation resistance. In the harsh marine environment, such as salt water, humidity and climate change, the welded mesh panels can maintain stable performance for a long time, reduce the need for maintenance and replacement, and greatly reduce the operating costs of marine projects.

Strength and Stability of welded wire mesh panel:

The structural design of the welded mesh panel makes it have high strength and stability, and can withstand the effects of wind, waves, tides and water pressure in the marine environment. Whether in offshore platforms, offshore bridges or offshore installations, welded mesh panels, as key components, can provide reliable support and protection.

Permeability and Flow Control of welded wire mesh panel:

The open structure of the welded mesh panel makes it have good permeability, which is conducive to the passage and discharge of water. In marine engineering, welded mesh panels can be used to construct the shell of marine structures, which can effectively control water flow and tides, reduce the influence of eddies and hydrodynamic forces, and improve the stability and safety of projects.

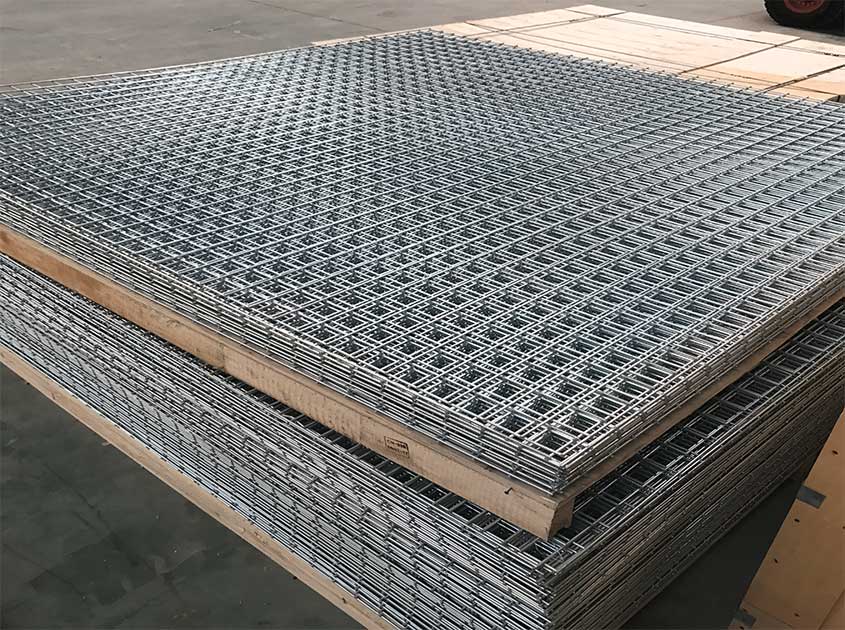

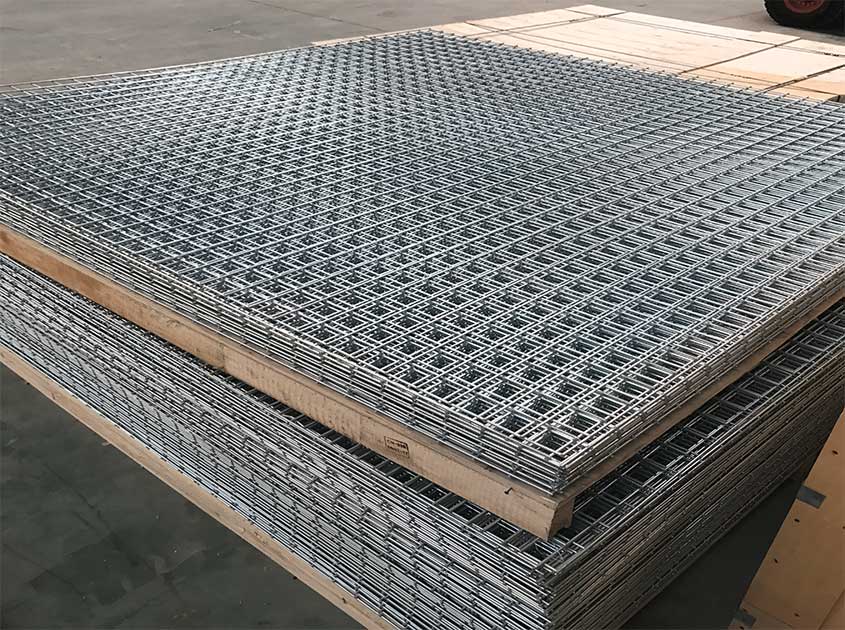

Wide range of applications of welded wire mesh panel:

Welded mesh panels are widely used in the field of marine engineering. It can be used for offshore platforms, offshore wind farms, submarine pipelines, guardrails and isolation of offshore installations, etc. Whether it is in the development of marine resources, marine protection or marine traffic construction, welded mesh panels play an indispensable role.

Sustainable development and environmental friendliness of welded wire mesh panel:

The materials of welded mesh panels are generally recyclable and reusable, with low environmental impact. In marine engineering, the use of welded mesh panels conforms to the principle of sustainable development and helps to protect the marine ecological environment and sustainable use of marine resources.

.jpg)

.png)