Introduction:

When it comes to fencing and agricultural applications, two popular options are chicken wire mesh and welded wire mesh. While both serve similar purposes, there are notable differences between the two. In this article, we will explore the dissimilarities between chicken wire mesh and welded wire mesh, highlighting their unique characteristics, applications, and advantages. Understanding these distinctions will help farmers and inpiduals make informed decisions when choosing the right type of wire mesh for their specific needs.

Construction and Design:

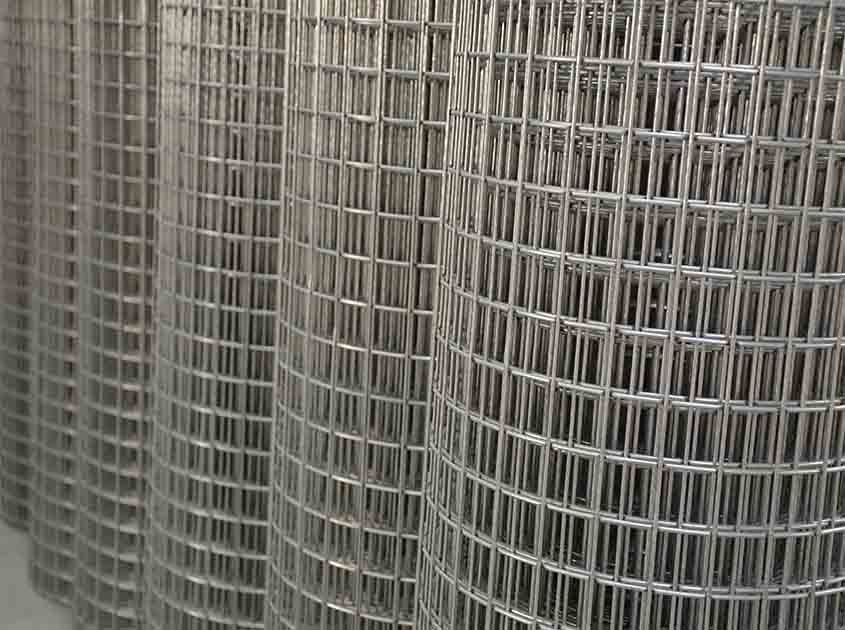

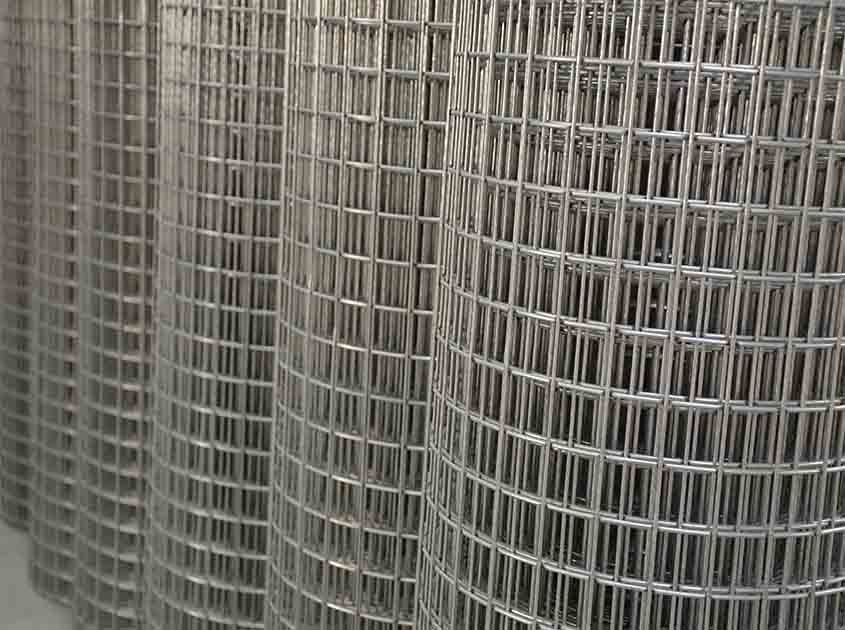

The primary difference between chicken wire mesh and welded wire mesh lies in their construction and design. Chicken wire mesh, also known as poultry netting, is made of lightweight, flexible wire twisted together in a hexagonal pattern. The hexagonal openings give it a characteristic honeycomb-like appearance. On the other hand, welded wire mesh is constructed by welding inpidual wires at their intersections, forming a grid-like pattern. The welded construction results in a rigid and sturdy mesh structure.

Wire Gauge and Thickness:

Another differentiating factor is the wire gauge and thickness used in chicken wire mesh and welded wire mesh. Chicken wire mesh typically consists of thinner wires, ranging from 19 to 22 gauge. The thinner gauge wires make it lightweight and flexible, suitable for applications such as poultry enclosures and garden fencing. In contrast, welded wire mesh tends to have thicker wires, commonly ranging from 14 to 12 gauge. The thicker gauge wires provide greater strength and rigidity, making it ideal for applications that require more durability and security.

Applications:

Chicken wire mesh and welded wire mesh find applications in various fields, but they excel in different areas. Chicken wire mesh is primarily used in poultry enclosures, garden fencing, and small animal enclosures. Its lightweight nature and flexible design make it suitable for containing small animals while allowing sufficient ventilation. Welded wire mesh, with its sturdier construction, is commonly employed in applications that require high strength and security. It is frequently used for livestock enclosures, perimeter fencing, and industrial purposes where a robust barrier is necessary.

Strength and Durability:

In terms of strength and durability, welded wire mesh has the upper hand. The welded intersections create a solid bond between the wires, resulting in a rigid and robust mesh structure. Welded wire mesh can withstand greater impact and pressure, making it suitable for enclosing larger animals and providing enhanced security. Chicken wire mesh, while sufficient for containing small animals and providing a barrier against pests, may not offer the same level of strength and durability as welded wire mesh.

Cost:

Cost is another factor to consider when comparing chicken wire mesh and welded wire mesh. Chicken wire mesh is generally more affordable compared to welded wire mesh. Its simpler construction and thinner gauge wires contribute to a lower cost per unit area. Welded wire mesh, with its stronger and more intricate design, tends to be slightly more expensive. However, the cost difference may vary depending on the specific gauge, material, and size requirements of the mesh.

.jpg)

.png)