Introduction:

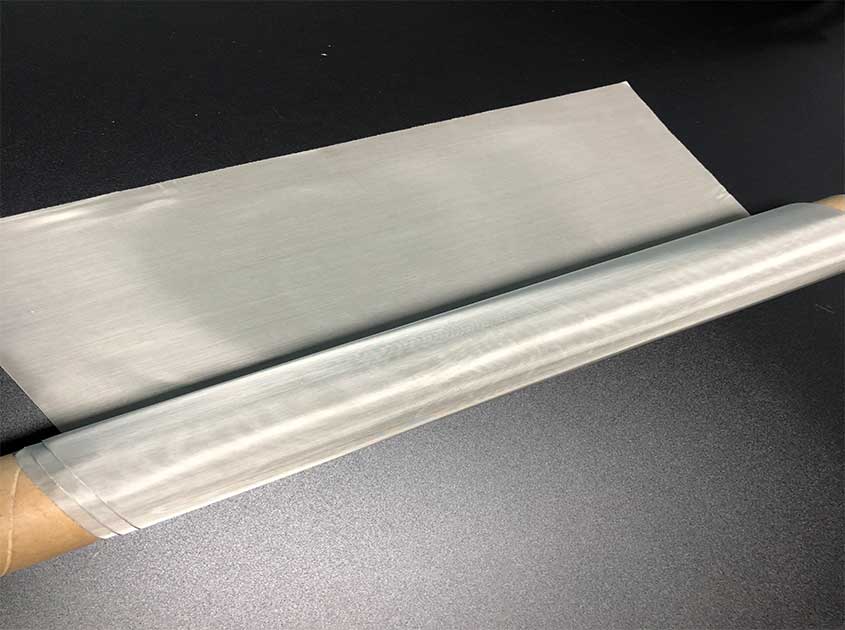

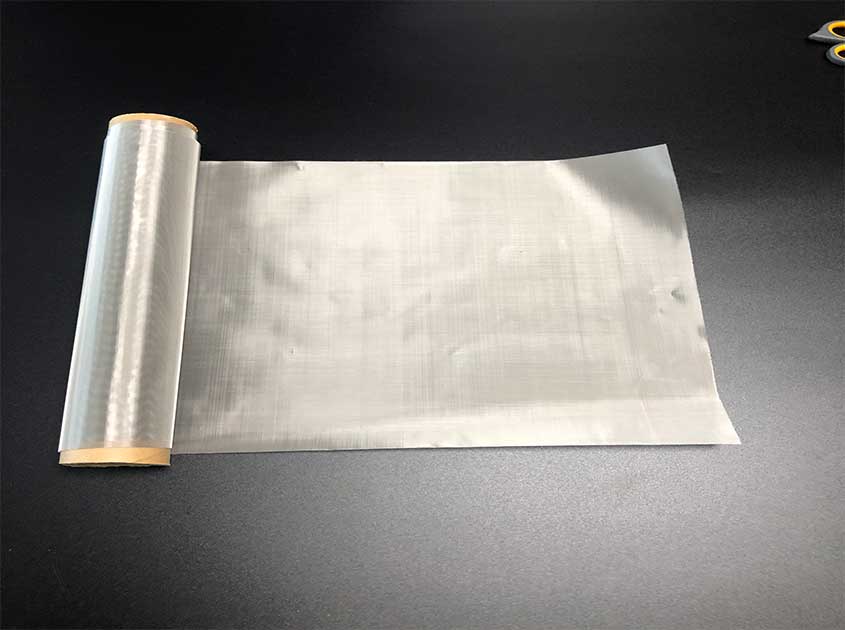

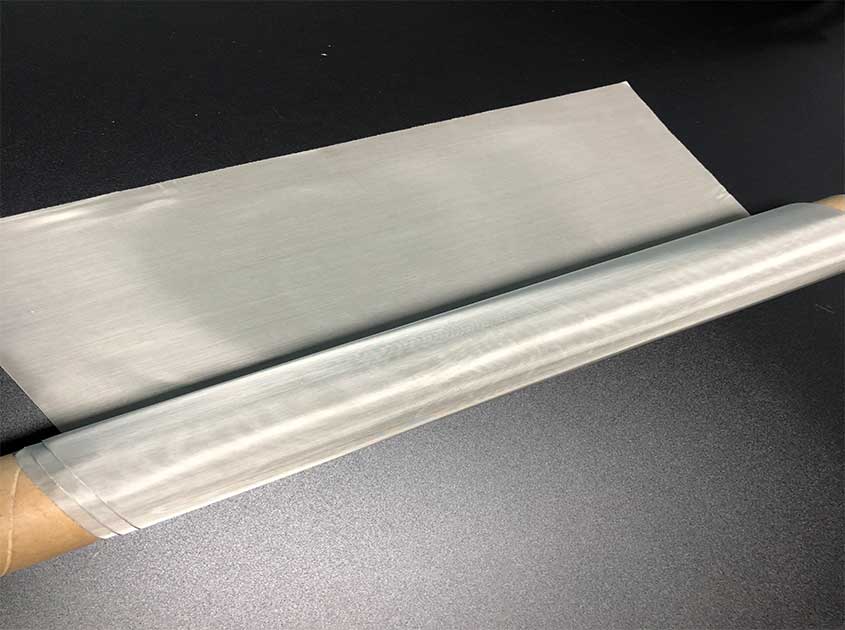

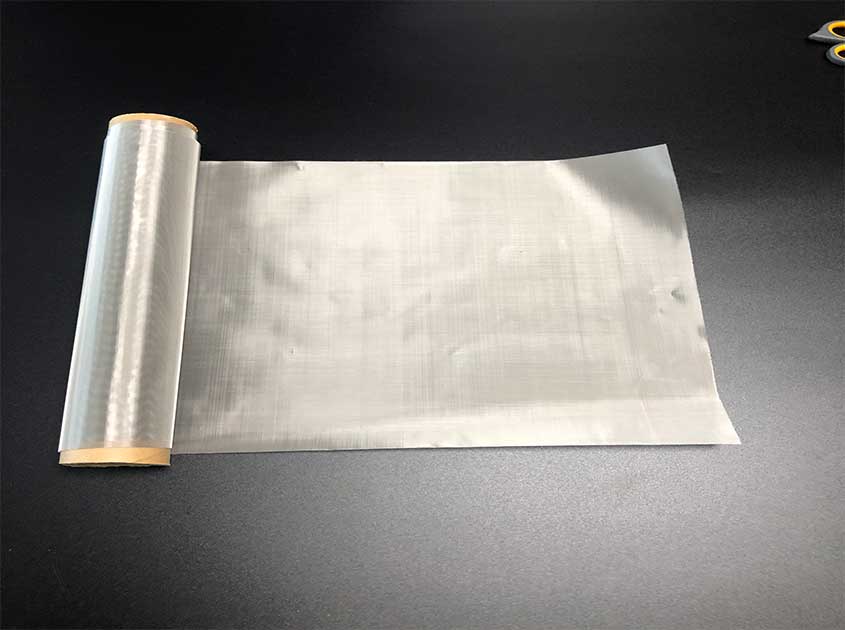

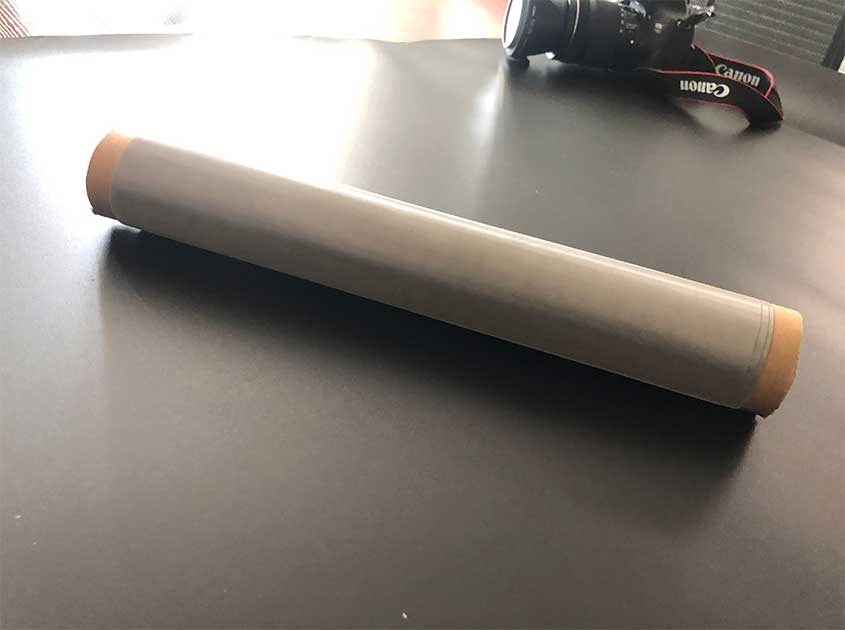

In the world of industrial and architectural applications, stainless steel wire mesh has emerged as a sustainable and long-lasting solution. With its exceptional durability, corrosion resistance, and versatile properties, stainless steel wire mesh offers numerous advantages over other mesh materials. This article explores the benefits and applications of stainless steel wire mesh in various industries, highlighting its contribution to sustainable design, longevity, and performance.

Superior Durability and Corrosion Resistance:

One of the key advantages of stainless steel wire mesh is its unmatched durability and corrosion resistance. Stainless steel is inherently resistant to rust, oxidation, and deterioration, even in harsh environmental conditions. This makes stainless steel wire mesh an ideal choice for applications that require longevity and resistance to moisture, chemicals, and UV exposure. Industries such as construction, mining, oil and gas, and marine engineering greatly benefit from the superior durability of stainless steel wire mesh, resulting in reduced maintenance costs and prolonged service life.

Sustainability and Environmental Friendliness:

Stainless steel wire mesh is a sustainable choice that aligns with environmentally conscious practices. Stainless steel is a recyclable material, and using stainless steel wire mesh reduces the need for frequent replacements, minimizing waste generation. Additionally, stainless steel production involves lower energy consumption and fewer harmful emissions compared to other metals. By opting for stainless steel wire mesh, industries contribute to resource conservation and support eco-friendly initiatives.

Versatile Applications in Industrial Settings:

Stainless steel wire mesh finds a wide range of applications in industrial settings. It serves as a reliable filtration medium for separating particles and controlling fluid flow in industries such as pharmaceuticals, food processing, and wastewater treatment. The high strength of stainless steel wire mesh makes it suitable for heavy-duty applications, including machine guards, safety enclosures, and conveyor belts. Its precise and uniform mesh openings enable accurate sieving and sorting in materials handling and mining operations.

Architectural Applications:

Beyond industrial settings, stainless steel wire mesh has gained popularity in architectural and design applications. Its aesthetic appeal, combined with durability, makes it an attractive choice for façades, interior screens, balustrades, and decorative elements. Stainless steel wire mesh offers transparency and airflow while providing security and protection. It can be custom-designed and fabricated into various patterns, sizes, and finishes to meet the unique design requirements of architectural projects.

Easy Maintenance and Hygiene:

Stainless steel wire mesh is easy to maintain and clean, making it ideal for industries that require stringent hygiene standards. The smooth surface of stainless steel prevents the accumulation of dirt, bacteria, and contaminants. Regular cleaning with mild detergents and water is usually sufficient to maintain its appearance and hygiene levels. This feature is particularly advantageous in applications such as food processing, pharmaceuticals, and healthcare facilities, where cleanliness is crucial.

.jpg)

.png)