Introduction:

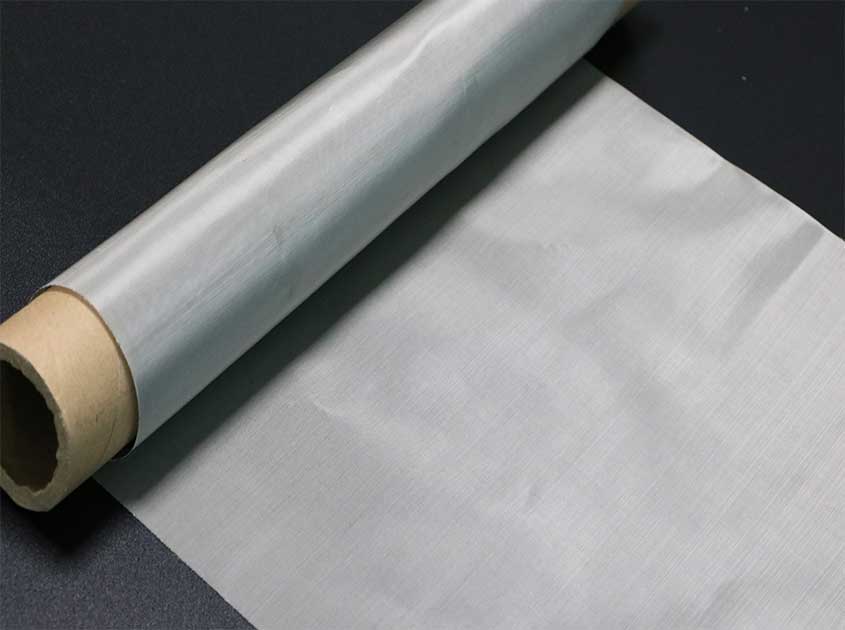

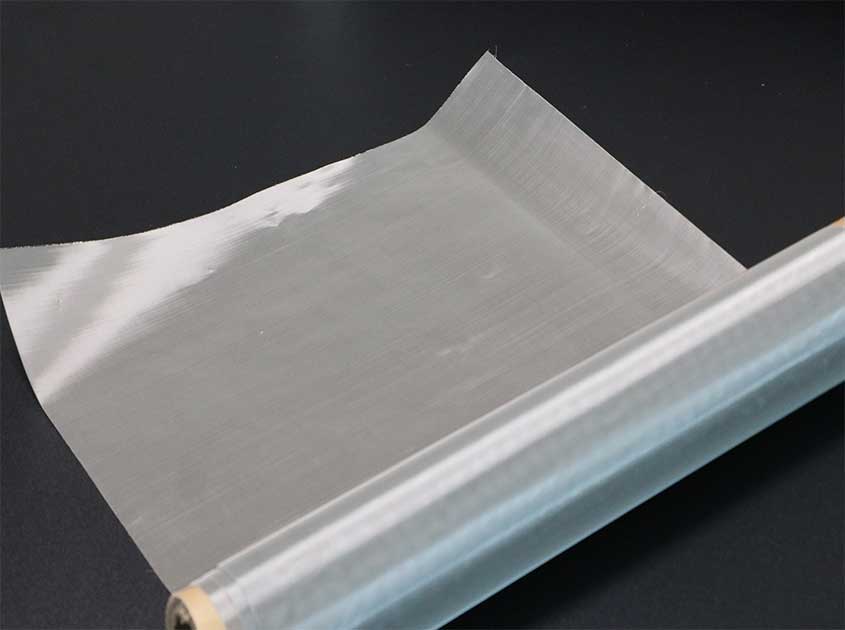

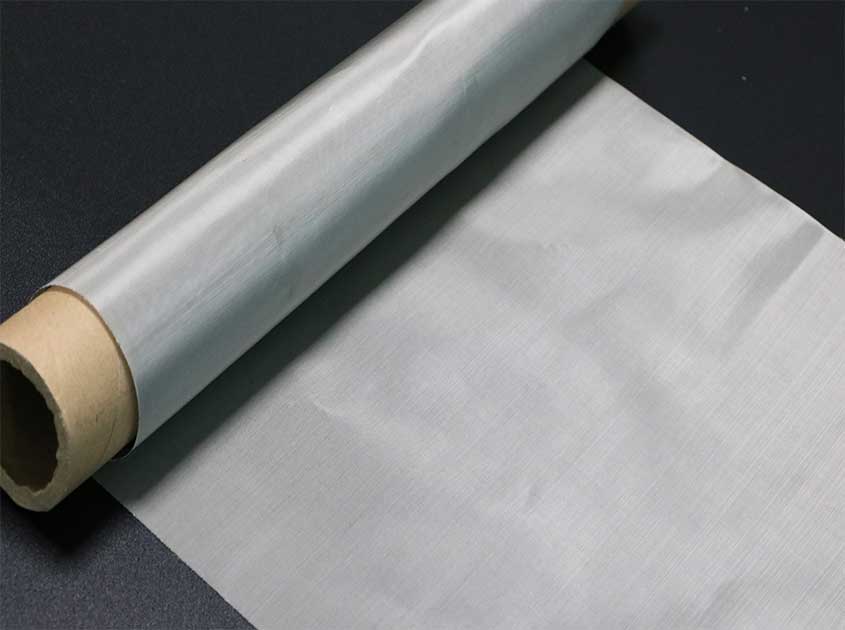

When it comes to selecting stainless steel wire mesh for your project, making the right choice is crucial. Stainless steel wire mesh offers excellent durability, corrosion resistance, and versatility, making it suitable for various applications. In this article, we will guide you through the factors to consider when choosing the right stainless steel wire mesh for your specific project needs.

Material Grade:

Stainless steel wire mesh is available in different grades, such as 304, 316, and 316L. Each grade offers varying degrees of corrosion resistance and strength. Consider the environmental conditions and exposure to corrosive elements that your project may encounter. For example, marine or coastal applications may require a higher-grade stainless steel wire mesh to withstand saltwater exposure. Evaluate the material grades and select the one that best suits your project requirements.

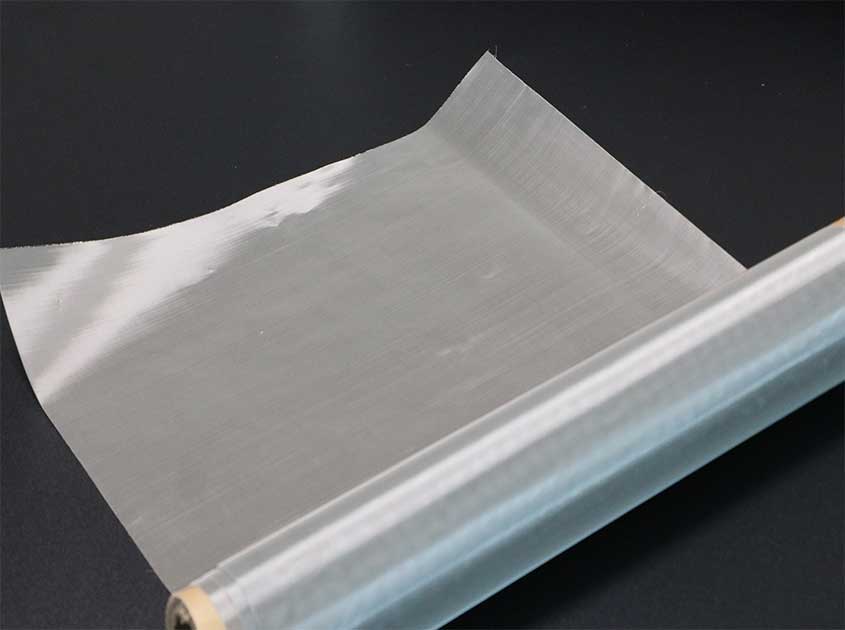

Wire Diameter and Mesh Size:

The wire diameter and mesh size are crucial factors to consider. The wire diameter determines the thickness and strength of the wire, while the mesh size refers to the number of openings per linear inch. For projects that require higher strength and durability, opt for a thicker wire diameter. The mesh size should be chosen based on the specific purpose of the wire mesh, considering factors such as filtration requirements, particle size retention, or desired airflow.

Weave Pattern:

Stainless steel wire mesh comes in various weave patterns, including plain weave, twill weave, and Dutch weave. Each pattern offers different characteristics and performance attributes. The plain weave is the most common and offers good strength and filtration properties. Twill weave provides greater stability and is suitable for heavy-duty applications. Dutch weave has excellent filtration capabilities and is often used in fine filtration applications. Choose the weave pattern that best suits the intended purpose and performance requirements of your project.

Application-Specific Considerations:

Consider the specific requirements of your project. Are you using the wire mesh for filtration, screening, fencing, or architectural purposes? Different applications may have specific requirements such as light transmission, airflow, or surface aesthetics. Assess these factors to choose the appropriate stainless steel wire mesh that meets the demands of your project.

Budget and Longevity:

Evaluate your budget and consider the longevity of the stainless steel wire mesh. While higher-grade stainless steel and thicker wire diameter may incur higher costs, they often provide better durability and longer service life. Balance your budget constraints with the desired performance and longevity of the wire mesh to make an informed decision.

.jpg)

.png)