Introduction:

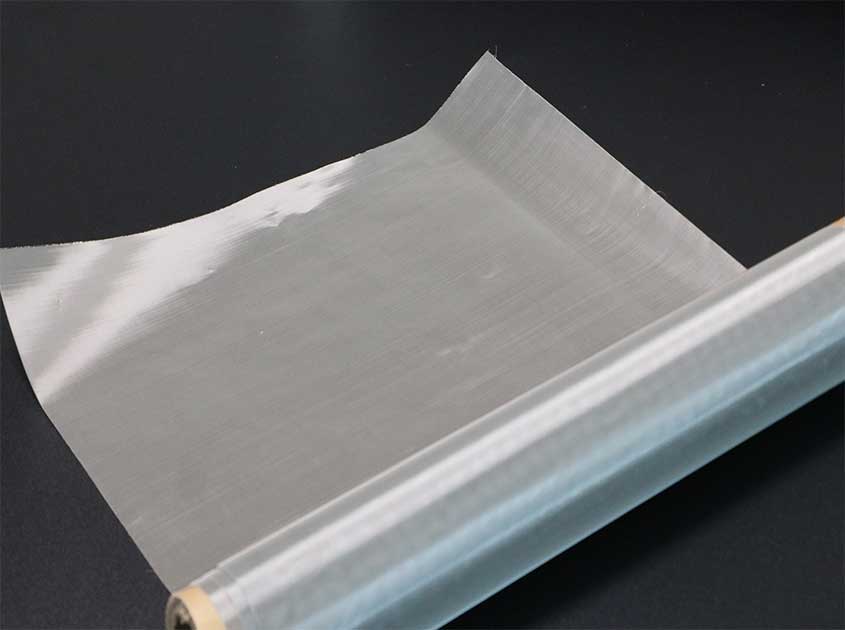

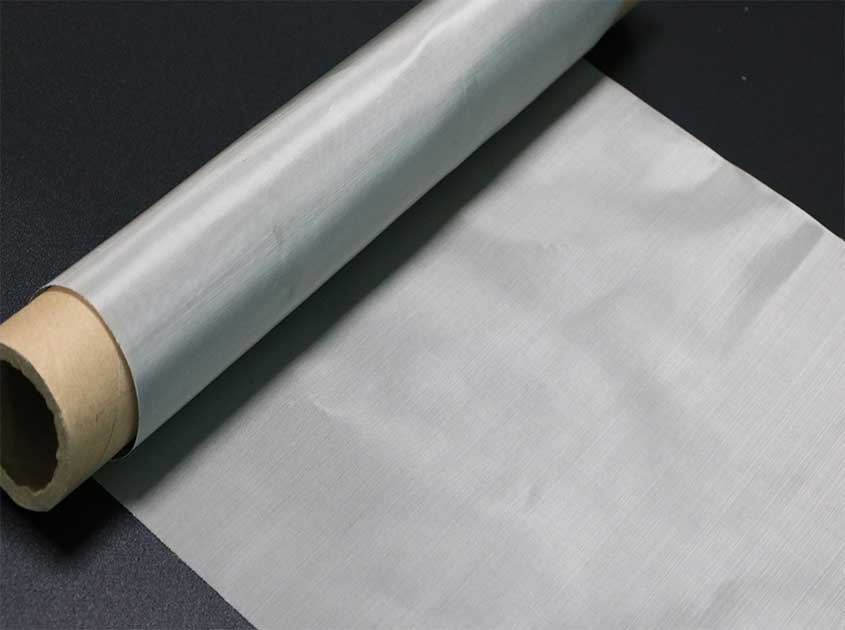

Stainless steel wire mesh has proven to be a reliable and effective solution for filtration and separation needs. In this article, we will explore the reasons why stainless steel wire mesh is widely regarded as a dependable choice in these critical processes.

Exceptional Strength and Durability:

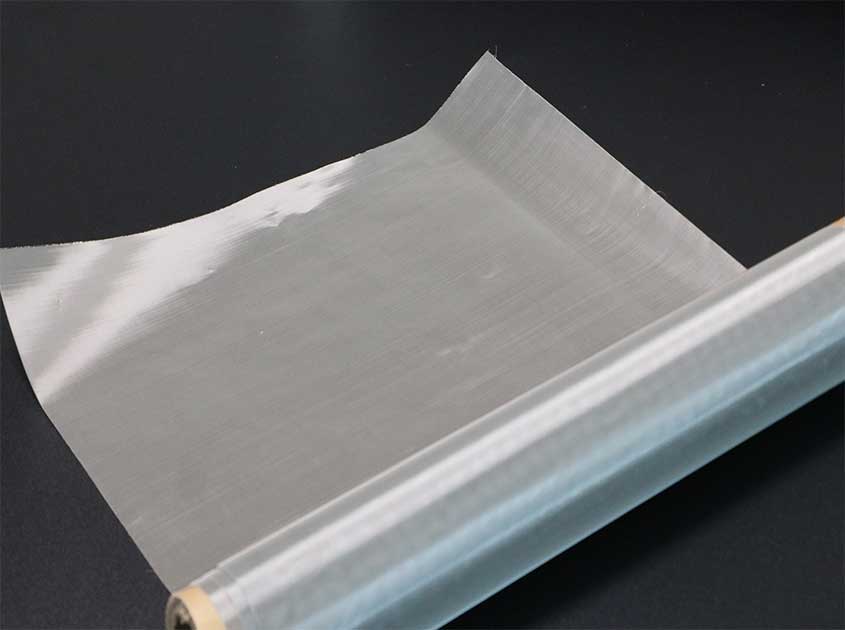

Stainless steel wire mesh is known for its exceptional strength and durability. The mesh is made from high-quality stainless steel, which provides excellent resistance against corrosion, chemicals, and extreme temperatures. This durability ensures that the wire mesh maintains its structural integrity and filtration efficiency over an extended period, even in demanding operating conditions.

Precise Filtration Capability:

The design and construction of stainless steel wire mesh result in precise filtration capability. The mesh is available in various weave patterns and mesh sizes, allowing for fine or coarse filtration depending on the application requirements. The uniformity and consistency of the wire mesh ensure accurate particle retention, allowing for efficient separation and filtration of solids, liquids, and gases.

Wide Chemical Compatibility:

Stainless steel wire mesh exhibits wide chemical compatibility, making it suitable for filtration and separation processes involving aggressive or corrosive substances. It can withstand exposure to acids, alkalis, solvents, and other harsh chemicals without compromising its structural integrity. This chemical resistance ensures that the wire mesh remains effective and reliable, even when exposed to challenging environments.

High Flow Rates and Low Pressure Drops:

Efficient filtration and separation processes require adequate flow rates while maintaining low pressure drops. Stainless steel wire mesh offers a balance between these two factors. The open structure of the mesh allows for high flow rates, ensuring efficient processing of liquids or gases. Simultaneously, the wire mesh design minimizes pressure drops, optimizing system performance and reducing energy consumption.

Easy Cleaning and Maintenance:

Stainless steel wire mesh is relatively easy to clean and maintain, ensuring consistent filtration performance. The smooth surface of the wire mesh prevents the accumulation of particles and contaminants, allowing for straightforward cleaning through methods such as backwashing, ultrasonic cleaning, or mechanical agitation. Routine maintenance involves inspecting the mesh for any damage or clogging and replacing or cleaning the mesh as needed.

.jpg)

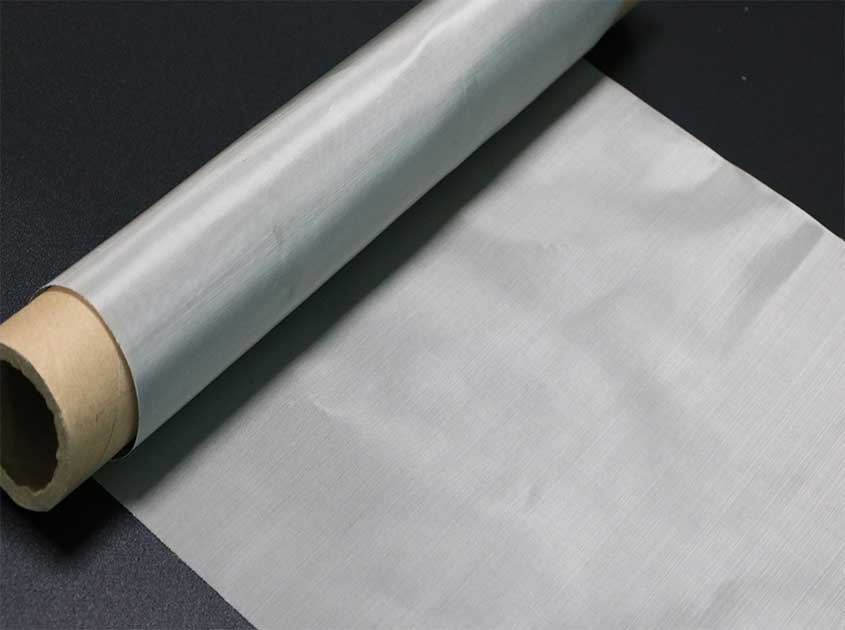

.png)