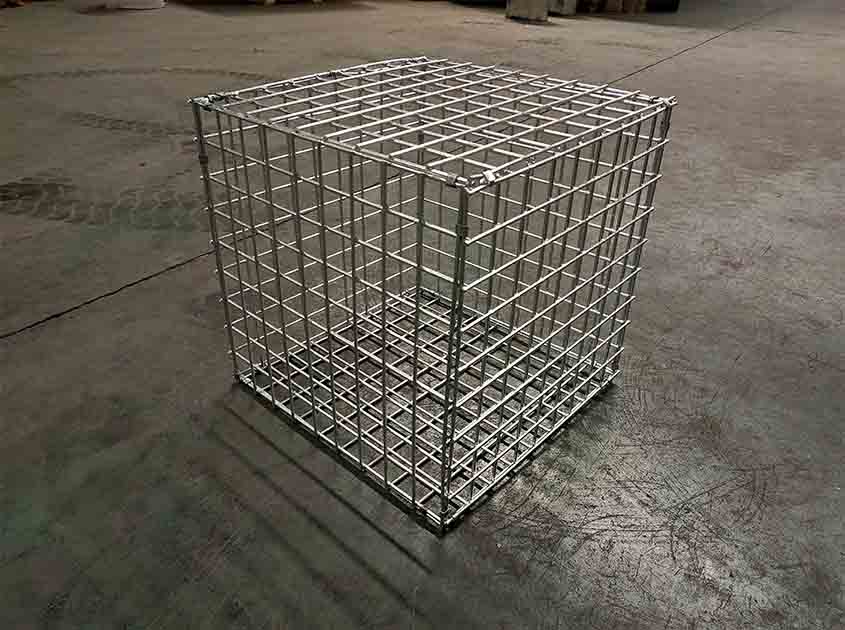

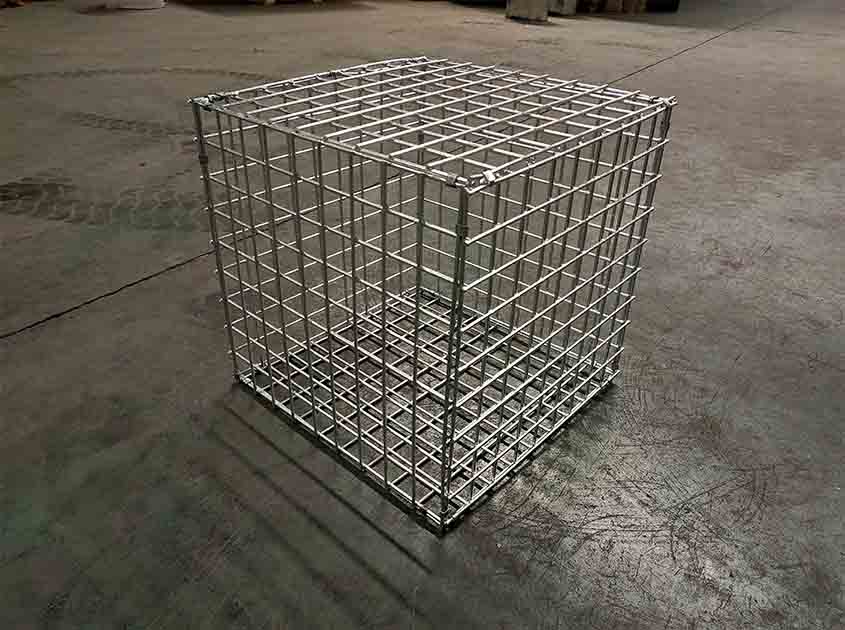

Galvanized wire mesh, renowned for its durability and corrosion resistance, is widely used in various applications. However, when considering its performance in environments with harsh chemicals, it is essential to assess its resistance to chemical corrosion. In this article, we will delve into the capabilities of galvanized wire mesh in withstanding exposure to harsh chemicals, providing insights into its suitability for such demanding environments.

Galvanized Coating:

Galvanized wire mesh is coated with a layer of zinc, which acts as a protective barrier against corrosion. The galvanization process involves immersing the wire mesh in a bath of molten zinc, allowing the zinc to bond to the underlying steel. This coating provides initial protection against rust and corrosion, making galvanized wire mesh suitable for various applications.

Chemical Resistance of Galvanized Wire Mesh:

Galvanized wire mesh exhibits moderate resistance to a wide range of chemicals. It can withstand exposure to mild acids, alkalis, and organic solvents found in typical environmental conditions. In applications where the concentration and exposure duration of chemicals are relatively low, galvanized wire mesh can provide satisfactory corrosion resistance.

Limitations and Considerations:

a. Highly Corrosive Chemicals:

Galvanized wire mesh may not be suitable for environments where it is continuously exposed to highly corrosive chemicals or extreme concentrations. Harsh chemicals, such as strong acids (e.g., sulfuric acid) or strong alkalis (e.g., sodium hydroxide), can react with the zinc coating, compromising its protective properties. Over time, prolonged exposure to such chemicals can result in degradation of the galvanized coating and potential corrosion of the underlying steel.

b. Abrasive Chemicals and Scratches:

Galvanized wire mesh may also be vulnerable to abrasion from chemical particulates or abrasive substances. If the zinc coating is scratched or damaged, the exposed steel can be susceptible to corrosion. It is crucial to handle galvanized wire mesh with care and avoid contact with abrasive materials that could compromise the integrity of the protective coating.

.jpg)

.png)