Introduction:

Stainless steel wire mesh is a versatile material widely used in various applications, including filtration, separation, and protection. The weaving technique employed during the manufacturing process plays a crucial role in determining the characteristics and performance of the wire mesh. In this article, we will delve into the options for stainless steel wire mesh weaving techniques. By exploring different weaving methods, their unique features, and the applications they are suitable for, we can gain a comprehensive understanding of the weaving options available for stainless steel wire mesh.

Plain Weave:

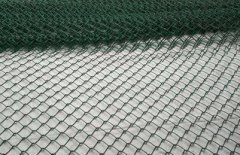

The plain weave is the most common and straightforward weaving technique for stainless steel wire mesh. It consists of an equal number of wires woven over and under each other, forming a simple crisscross pattern. This creates a strong and stable mesh with uniform openings. The plain weave is suitable for general applications, including particle filtration, ventilation, and insect screens.

Twill Weave:

Twill weave involves interlacing wires in a diagonal pattern, resulting in a distinctive herringbone or zigzag appearance. This weaving technique creates a tight and stable mesh structure, offering increased strength and durability. The twill weave provides a higher level of filtration and is often used in applications requiring fine particle retention, such as industrial filtration, sieving, and sifting.

Dutch Weave:

Dutch weave, also known as Hollander weave, is characterized by a higher density of wires in one direction, creating smaller openings and a denser mesh. It is achieved by using thicker warp wires and a thinner weft wire configuration. Dutch weave offers exceptional strength, stability, and particle retention capabilities. It is commonly used in applications where precise filtration and separation of fine particles are required, such as hydraulic systems, chemical processing, and oil and gas industries.

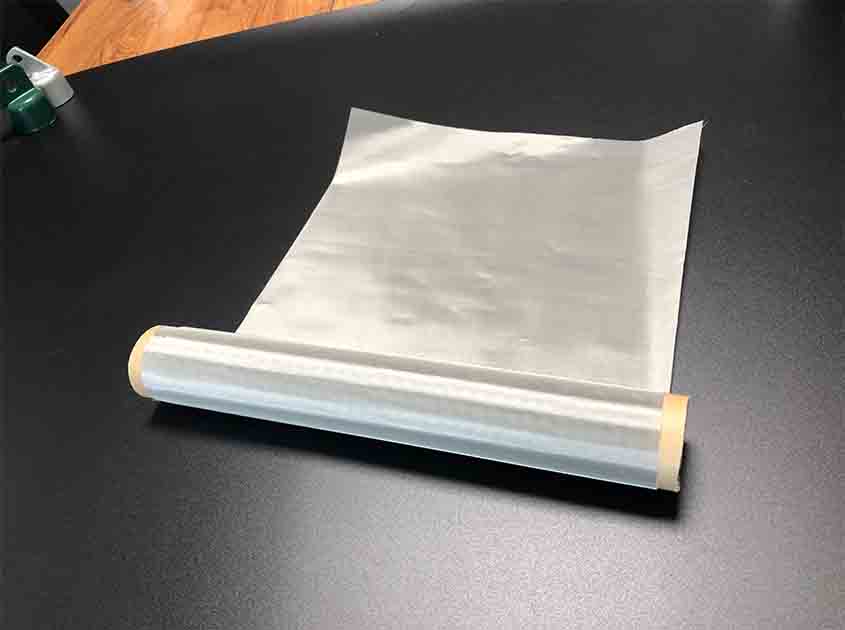

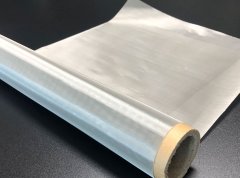

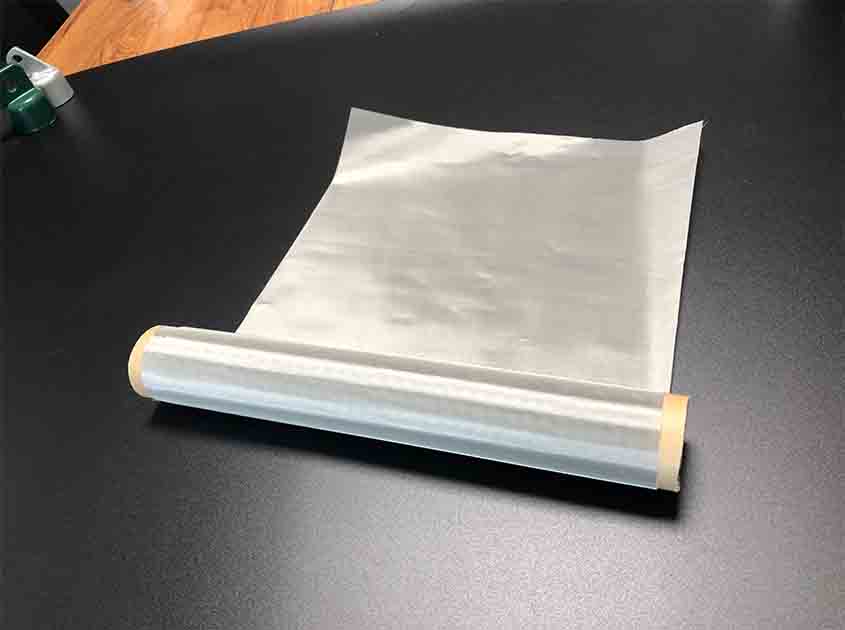

.jpg)

.png)